Pad Printing

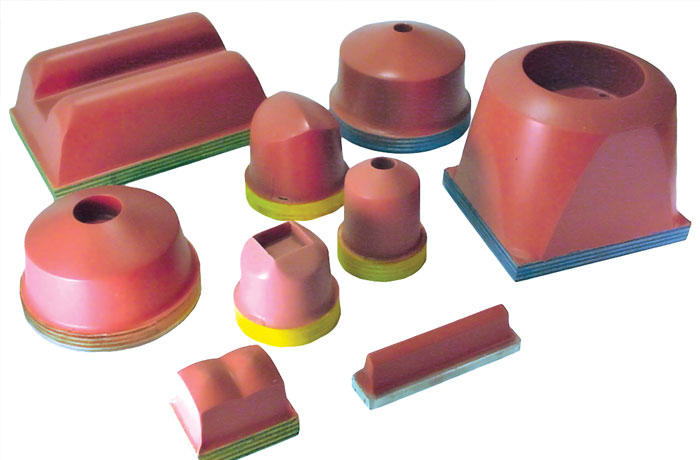

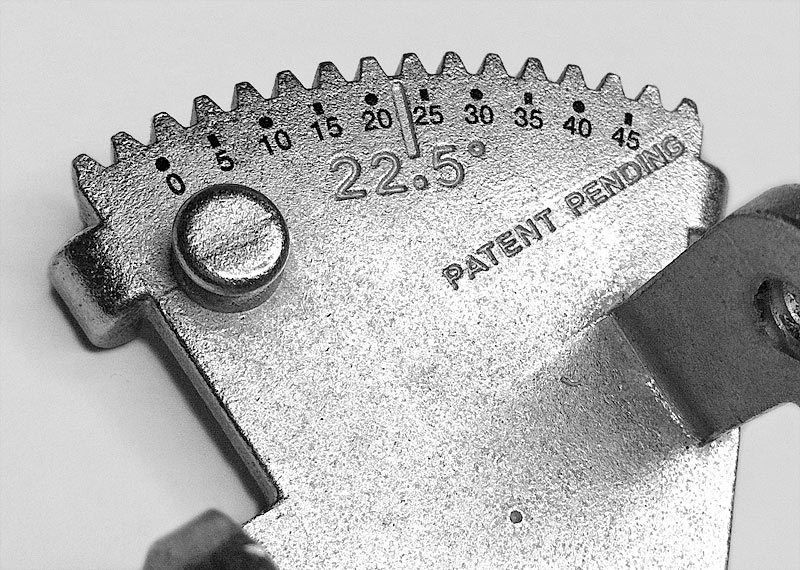

Deco Tech is the leading pad printing supplier & manufacturer in North America (United States & Canada). We provide pad printing machines, silicone pads, plates or clichés, inks, solvents, ink cups, cleaning equipment, exposure units and more.