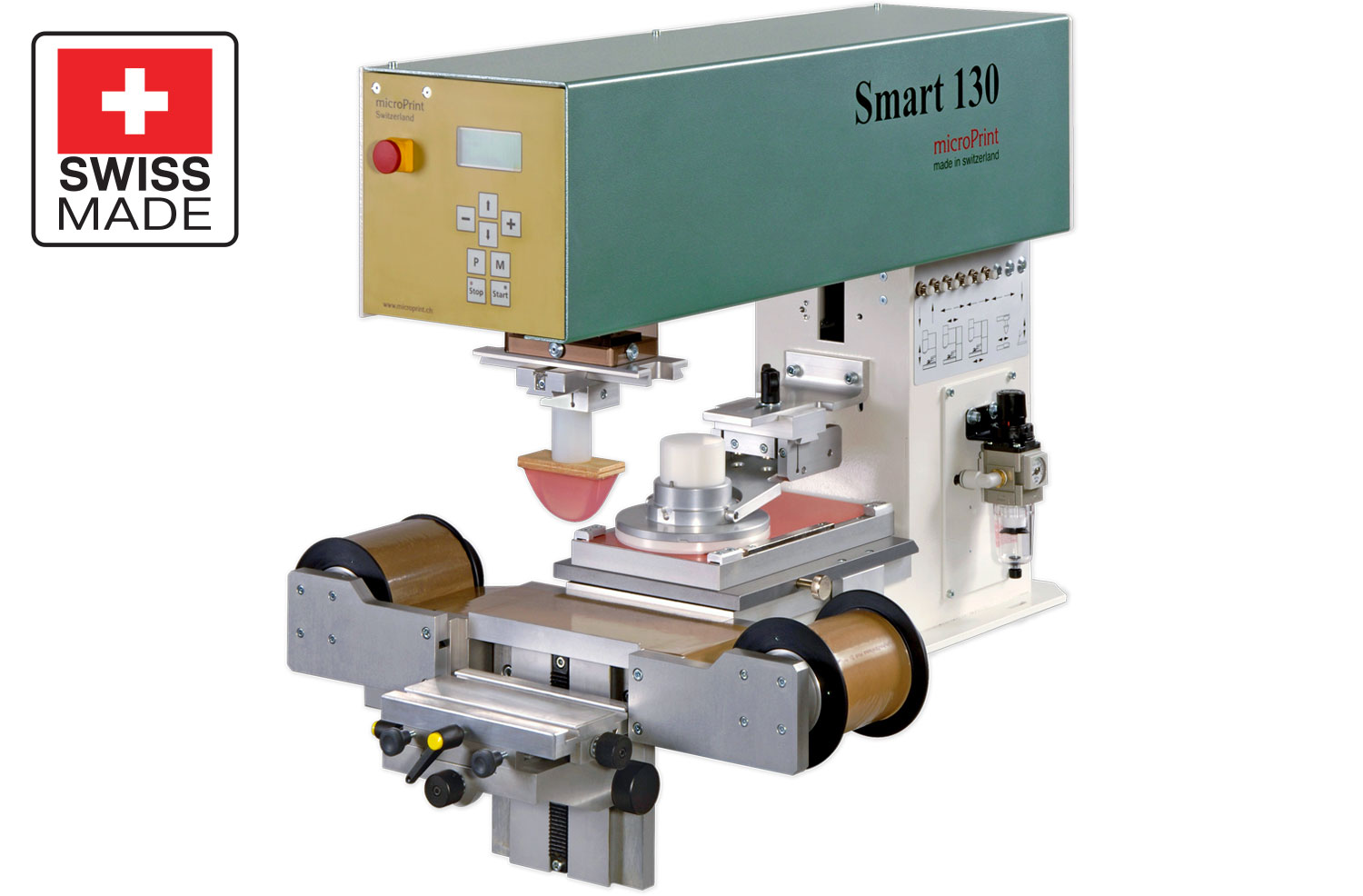

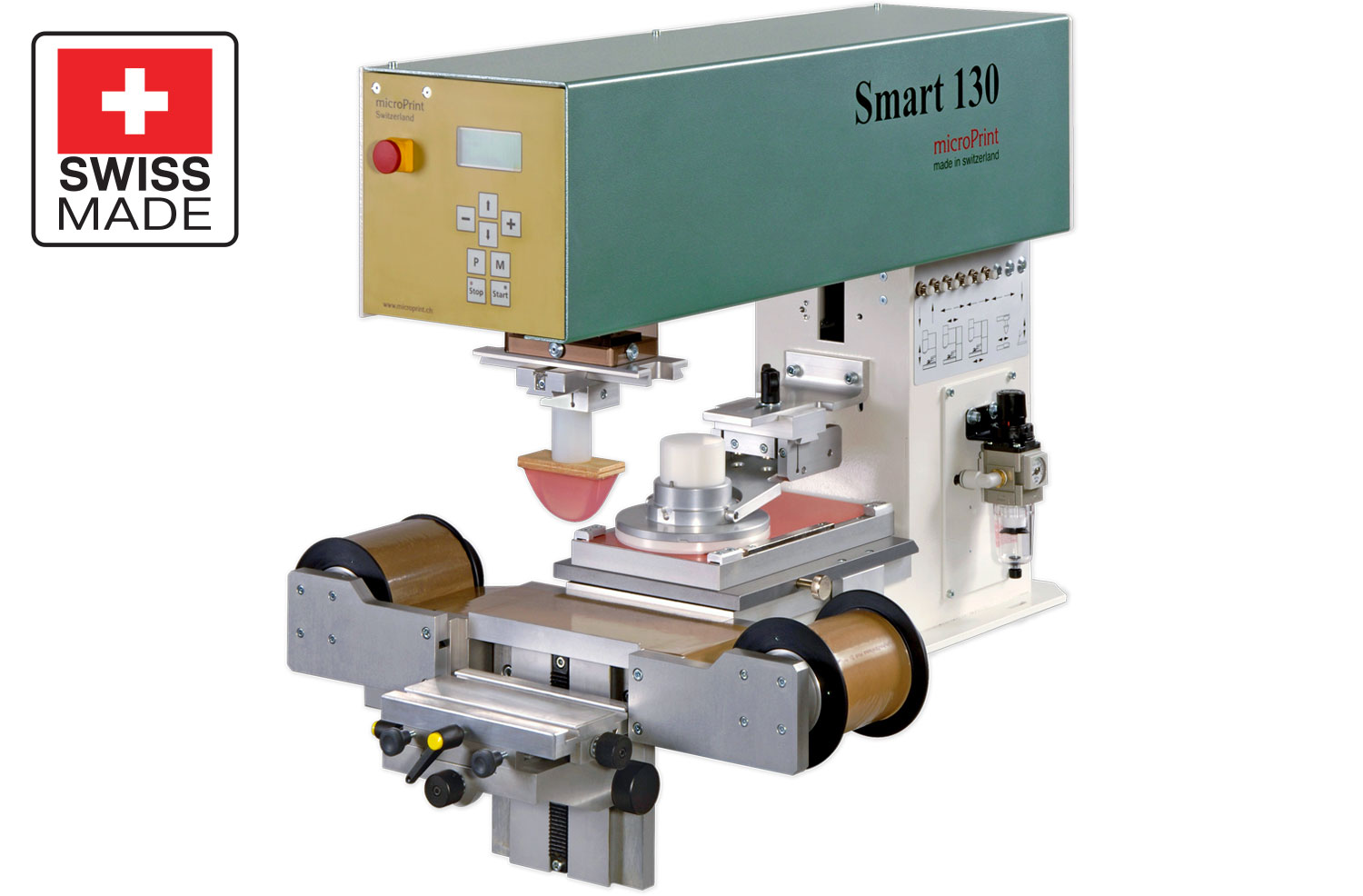

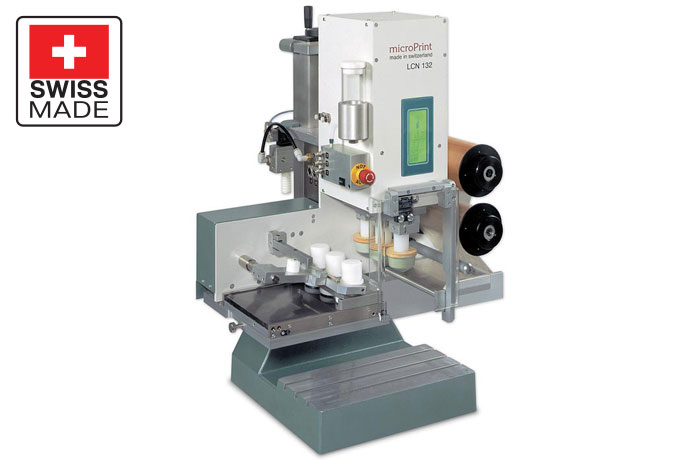

Smart 130 Pad Printing Machine

Swiss precision one color closed ink cup pad printing machine.

Deco Tech is the industry leader in providing turnkey pad printing automations. With nearly four decades of experience, we have been involved with several hundred automated pad printing systems, ranging from simple semi-automated machines to highly complex full automations with auto loading and unloading.

Swiss precision one color closed ink cup pad printing machine.

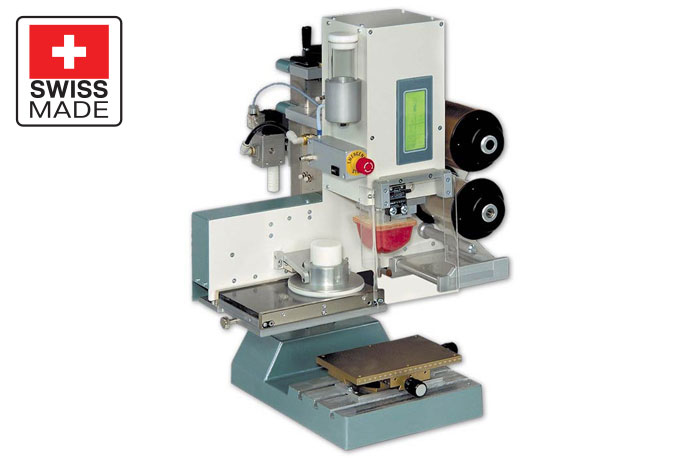

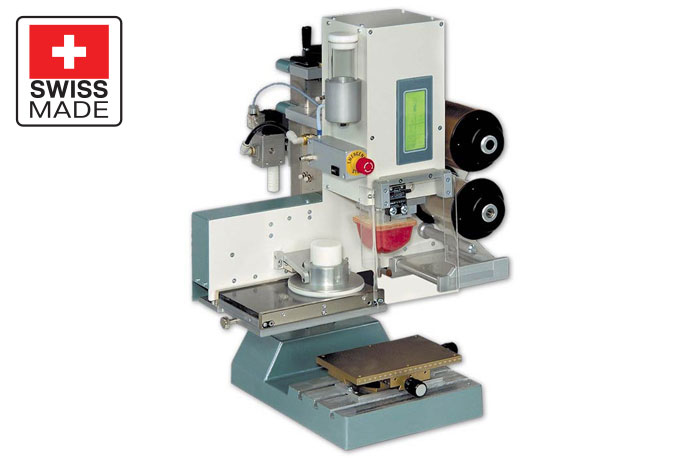

Swiss precision one to three color closed ink cup pad printing machine.

Swiss precision one color closed ink cup pad printing machine with automatic pad cleaning.

Swiss precision one color closed ink cup pad printing machine with automatic pad cleaning.

Swiss precision multi-color closed ink cup pad printing machine with automatic pad cleaning.

Swiss precision pad printing machine with automatic pad cleaning and ink cups up to 120mm.

Swiss precision pad printing machine with automatic pad cleaning and ink cups up to 140mm.

Swiss precision two to four color modular pad printing machine with automatic pad cleaning and ink cups up to 120mm.

One color closed cup pad printing machine with linear servo-driven ink cup slide attachment.

Linear motor driven CNC pad printing machine for single or multi-color pad printing on complex shaped parts.

Linear motor driven CNC pad printing machine for single or multi-color pad printing on complex shaped parts.

Motor driven closed ink cup pad printing machine with 86mm ink cup max.

Motor driven closed ink cup pad printing machine with 120mm ink cup max.

Motor driven closed ink cup pad printing machine with 160mm ink cup max.

Motor driven closed ink cup pad printing machine with 200mm ink cup max.

The 5-STAR is a servo-driven rotary indexing pad-printing machine that is a true workhorse.

The microPrint model MSS-130 is a specially designed pad printer that can pivot the printing pad upward 90° to print on the horizontal plane.

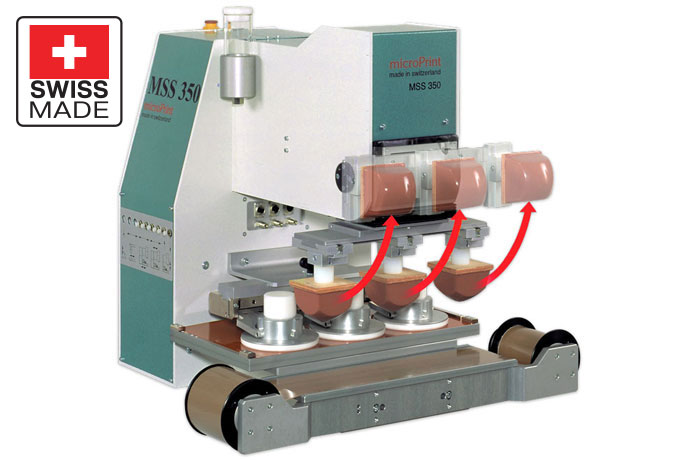

The microPrint model MSS-350 is a multi color pad printing machine that pivots the pad upwards 90° to print on the horizontal plane.

microPrint part rotation, standard pad printing automation component.

Multi-axis robot automation device for microPrint pad printing automations.

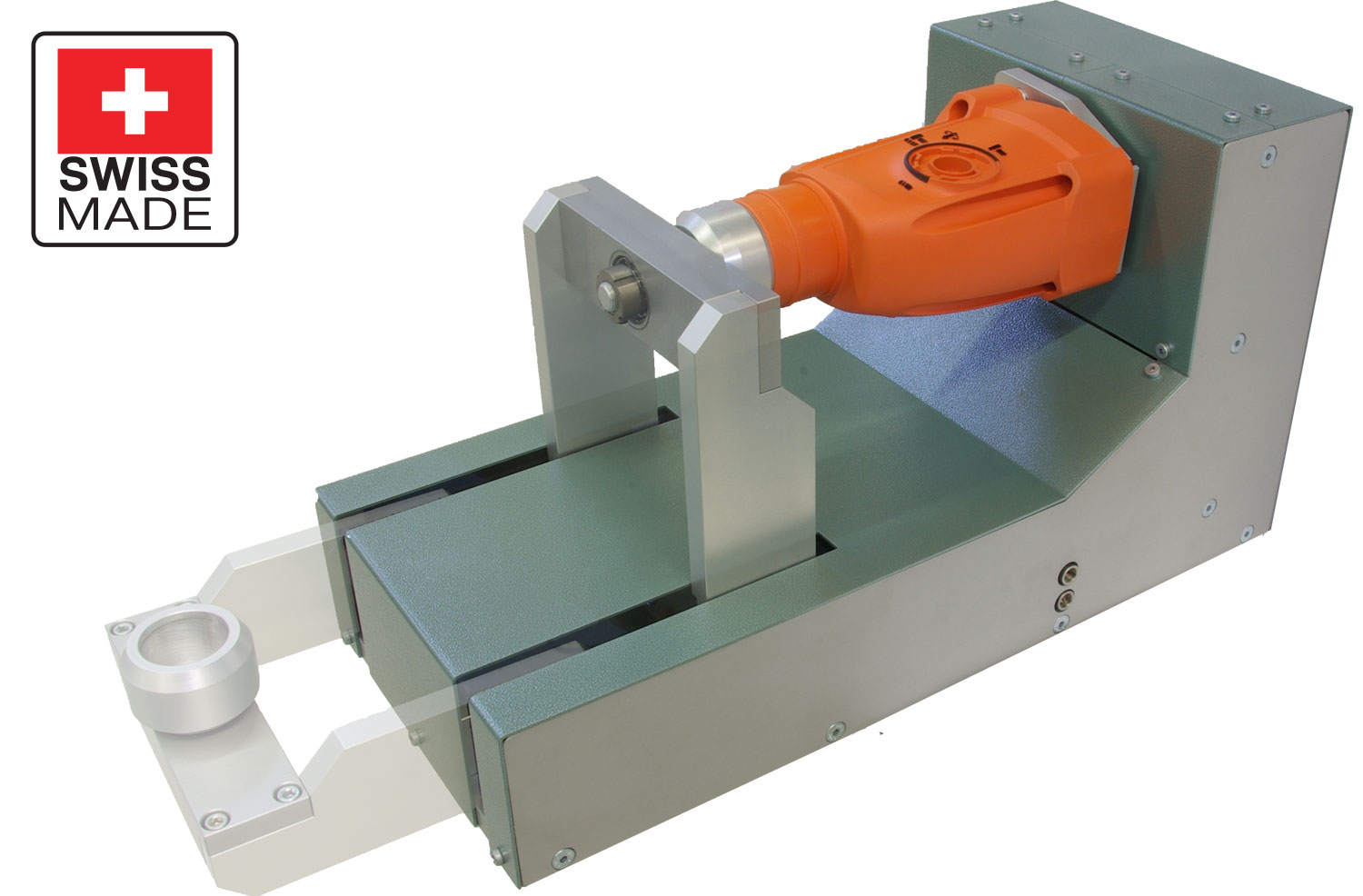

Servo-driven ball screw linear part shuttle for microPrint pad printing machines.

Servo-driven racetrack indexer for microPrint brand pad print machinery.

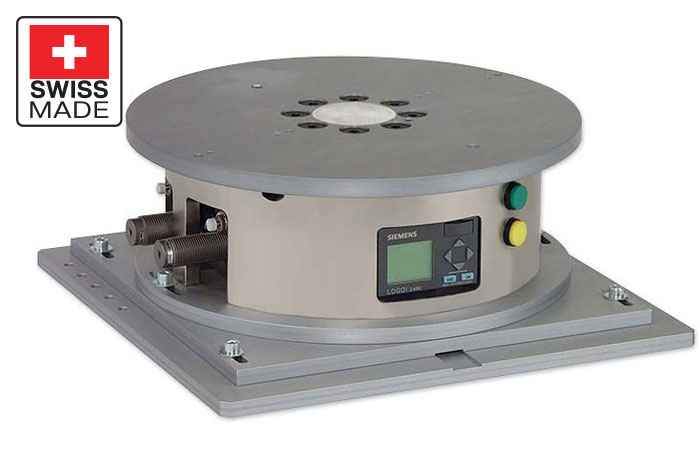

microPrint two station pneumatic rotary indexing table for faster part loading.

These rotary hammer parts were pad printed on the microPrint LCN-151 pad printer and the graphics are applied to both sides of the part with an automatic turning device.

These decorative pen barrels were pad printed on the microPrint Modul-130 machinery in a fully automated system.

The microPrint 5-STAR is well suited for pad printing on model train cars with up to five colors.

These center wheel caps were pad printing on the microPrint LCN-131 machinery.

These Hot and Cold graphics were pad printed on a microPrint LCN-131 pad printer.

The microPrint 5-STAR is well suited for pad printing on model train cars with up to five colors.

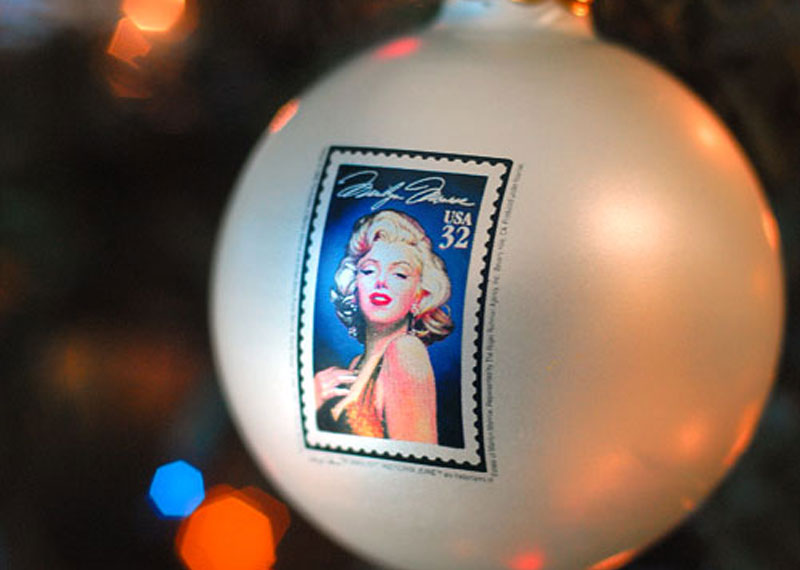

All types of Christmas Tree Ornaments can be pad printed on the microPrint 5-STAR.

1040 Segovia Circle

Placentia, California 92870 U.S.