Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Deco Tech is the leading pad printing supplier & manufacturer in North America (United States & Canada). We provide pad printing machines, silicone pads, plates or clichés, inks, solvents, ink cups, cleaning equipment, exposure units and more.

Deco Tech provides industry-leading screen printing solutions, featuring cutting-edge flatbed and cylindrical screen printing machines. Our comprehensive offerings include high-quality UV-curable inks and custom screen-making services, ensuring vibrant, durable prints for packaging, electronics, and promotional items.

Discover Deco Tech's state-of-the-art digital printing technology, designed for high-speed, direct-to-object printing. Our advanced systems deliver precise, full-color graphics on various surfaces, making them ideal for applications in cosmetics, beverages, and industrial branding. Achieve unmatched efficiency and superior print quality.

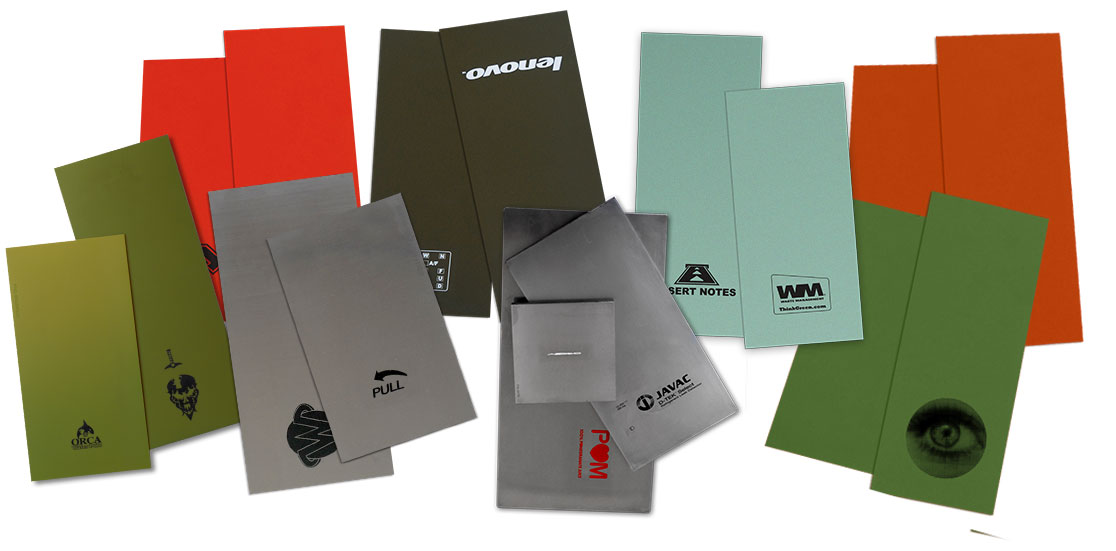

Deco Tech specializes in custom decorating services, including pad printing, screen printing and heat transfer. We provide tailored solutions to enhance product branding with sharp, vibrant designs, offering durable finishes for bottles, containers, and other consumer goods.

Advanced surface treating systems, including corona, plasma, and flame treatments. Our solutions improve adhesion on plastics, metals, and glass, ensuring superior ink bonding for pad, screen, and digital printing applications

Access Deco Tech's premium consumables, including Swiss-made Printcolor inks, durable silicone pads, precision-engineered clichés, and essential printing supplies. Our consumables ensure consistent, high-quality production outcomes for pad, screen, and digital printing processes

Deco Tech supplies Swiss-engineered microPrint pad printing machines and our own Deco Tech pad printers, trusted across North America for precision and repeatability. Our lineup covers single-color, multi-color, and fully automated pad printing solutions designed for industrial production of plastics, metals, and medical devices. With over 35 years of experience, we deliver both the equipment and technical expertise you need.

We provide high-performance screen printing machines from INO, Deco Tech, and RokuPrint, designed for bottles, jars, flat parts, and specialty components. Our automatic and semi-automatic screen printers offer precise registration, durable builds, and consistent quality across high-volume runs. Backed by decades of real-world expertise, our team ensures your industrial screen printing operation runs at peak performance.

Deco Tech provides Quantix digital UV inkjet printers designed for aluminum cans, bottles, containers, drinkware, and specialty products. These direct-to-object UV printers deliver full-color, photo-quality graphics with high-speed UV curing, eliminating the need for screens or plates. Perfect for short runs, personalization, and on-demand production, our industrial digital printing solutions offer fast setup, superior adhesion, and reliable performance.

Deco Tech supplies precision silicone pads for all types of pad printing applications. Our pads are engineered for optimal ink transfer, sharp detail, and long-lasting durability. Available in a wide range of shapes, durometers, and sizes, our pads are made in the USA to exacting standards—ensuring consistent quality and performance across every production run.

Deco Tech provides expert screen making services for industrial screen printing applications. We supply high-tension frames, mesh stretching, stencil application, and screen exposure using high-quality emulsions. Whether you're printing on flat, curved, or specialty substrates, our in-house screen making ensures precision, consistency, and durability. Ideal for graphics, membrane switches, medical parts, and printed electronics.

In our in-house ink lab, we custom blend Printcolor brand inks and mix up small or large batches of both UV screen printing inks and pad printing inks in custom Pantone color formulas, or we can match our inks to any color swatch you provide. Furthermore, we offer certifications for a variety of needs including medical grade Class VI and various automotive industry specs for both indoor and outdoor applications.

We prepare your artwork for high-quality printing across pad, screen, and digital processes. Our services include file cleanup, vector conversion, halftone creation, and trapping to ensure clean, print-ready graphics. Designed to maximize efficiency and print accuracy on every job.

Deco Tech supplies premium clichés for pad printing, including alcohol wash, water wash, laser-etched, and thick and thin steel plates. Our clichés are engineered for high-resolution printing, long-lasting durability, and compatibility with all major pad printing systems. We offer in-stock, pre-cut, and punched plates for fast, in-house processing—ideal for short-run to high-volume production.

Our expert technicians provide full technical support for pad printing, screen printing, and digital decorating equipment. Services include on-site troubleshooting, remote diagnostics, calibration, and process optimization to keep your production running efficiently and minimize downtime.

Discover in-depth articles on pad printing, screen printing, digital decoration, printing inks, silicone pads, viscosity control systems, and advanced production techniques.

The Swiss-engineered VISCOMATIC™ system ensures consistent ink viscosity for pad printing, enhancing print quality, efficiency, and color stability. Specifically designed for microPrint machines, this automatic solution helps reduce ink waste, improve consistency, and extend production uptime.

Pad Printing is the process of transferring 2-D images onto 3-D objects of various materials made from a variety of substrates. This is achieved by using an indirect offset (gravure) printing process that allows an image to be transferred from a printing plate (cliche) with a silicone pad onto an object. The Pad Printing process is becoming increasingly popular to many industries every year including automotive, medical, toys, promotional and electronic objects (circuit boards). Pad printing has conquered market shares (over hot stamping and screen printing) since the early 1970's, especially in complex printing areas.

One of the most frequently asked questions in the early stages of learning the do's and don'ts of the pad printing process is, "How do I know what pad to use for this part?"

Learn how to select the right silicone pad for pad printing based on part shape, artwork, and print requirements. A must-read for print quality and consistency.

Some of our satisfied customers