Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Deco Tech designs and builds linear conveyor corona treat systems for pre-treatment of plastics and these corona treat automations are built to our customers precise needs.

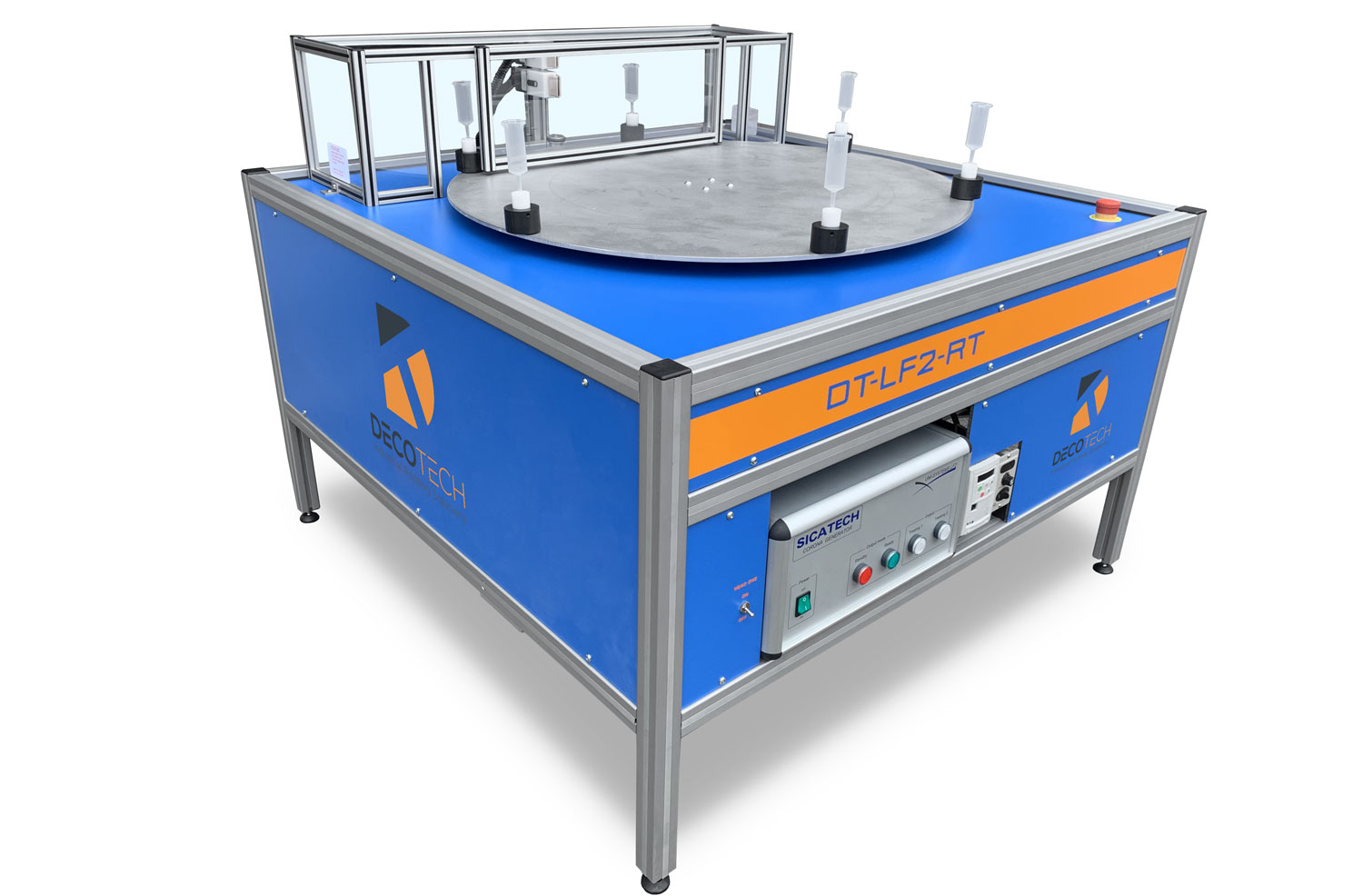

This is a Deco Tech built 6 station rotary indexing table corona pre-treating system outfitted with a SicaTech LF-2, two headed low frequency corona treating unit to pre-treat 360o around the barrel and lip of these parts. This corona treating system is fully guarded and parts are manually loaded and unloaded from the fixtures. Corona pre-treatment of PP and PE substrates greatly increases the inks adhesion. Deco Tech fabricates corona treating systems to pre-treat virtually any flat or 3D surfaces. Call the experts at (714) 639-DECO to find out more.

This is a Deco Tech built automated corona pre-treater with variable speed linear conveyer. This unit is safely guarded and it is outfitted with a carbon particle air filter/scrubber to remove ozone from the work place. The parts are manually placed onto the belt and the corona treatment begins automatically when the fiber optic sensor is activated. The system will automatically shut itself off when parts are no longer detected (controlled via a timer).

Product passing by the corona treating head to pre-treat the 3D part in the correct location. The pre-treatment of these nylon parts greatly increases the inks adhesion to these parts. Deco Tech fabricates corona treating systems to pre-treat virtually any flat or 3D surface.

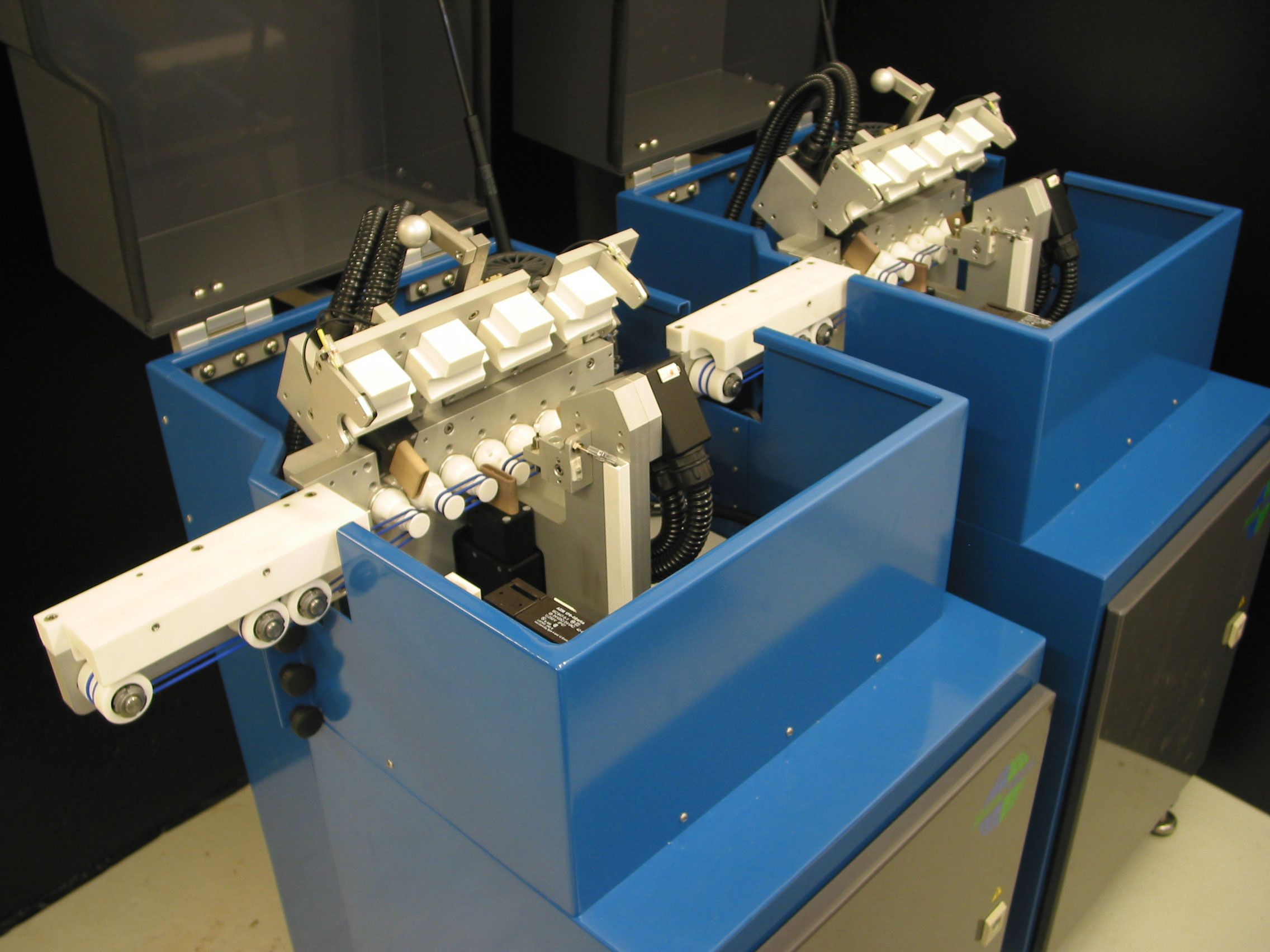

This is a automated corona treating system from SICA TECH that is pre-treating a lancing device for blood glucose testing. The parts are corona treated prior to pad printing for high quality ink adhesion. These medical parts are completely corona treated 360° and the company logo is printed on the pens' spring clip.