Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Deco Tech manufactures a complete lineup of high-performance silicone pads designed for the most demanding pad printing applications. Whether you're printing on medical components, automotive parts, consumer electronics, or textured promotional products, our premium pads are engineered for superior ink transfer, long life, and consistent performance.

We offer three advanced silicone formulations to suit nearly any production challenge:

DuraPro™, Stat-X™, and Printz™.

At Deco Tech, we don’t just sell premium silicone pads—we engineer and mold them to fit your exact printing requirements. From one-off prototypes to high-volume production, our team can design custom pad shapes and sizes based on your artwork, substrate, geometry, and ink system.

Each of our proprietary silicone formulations delivers unique advantages:

Trusted since 1987 and made in Southern California, Deco Tech pads are precision-molded in-house and used by top manufacturers across industries for maximum durability, print clarity, and repeatability.

Pad selection is critical. Every printed part has unique surface contours, ink requirements, and material characteristics that can affect print quality. Choosing the right pad ensures proper ink pickup, smooth transfer, and crisp image definition—especially on challenging 3D surfaces.

Use the right formulation for your job:

Need help selecting the right pad for your application? Contact our experts at sales@decotechgroup.com or call 714-639-DECO.

Trusted by leading manufacturers since 1997, DuraPro™ is our flagship premium silicone pad formulation. Made from the highest-grade German silicone rubber, DuraPro™ pads deliver:

Available in hardness ranges from 65 to 20 Shore A (00 scale), DuraPro™ is the benchmark material by which all others are measured. It’s the industry standard for consistent print quality and long pad life.

Stat-X™ silicone pads are engineered to eliminate the #1 enemy of sharp pad printing: static electricity. Standard pads can build up static during printing, leading to issues such as:

Stat-X™ solves these problems with an innovative, conductive silicone compound that cannot be charged with static electricity. The result:

Stat-X™ pads are ideal for electronics, medical devices, and other cleanroom or static-sensitive applications. Available in 65 to 40 Shore A durometer.

Looking for performance and affordability? Printz™ is our newest formulation and is rapidly becoming the pad of choice for many customers.

Printz™ pads are an excellent fit for budget-conscious operations that still demand high print quality and durability. Available in 65 to 40 Shore A durometer.

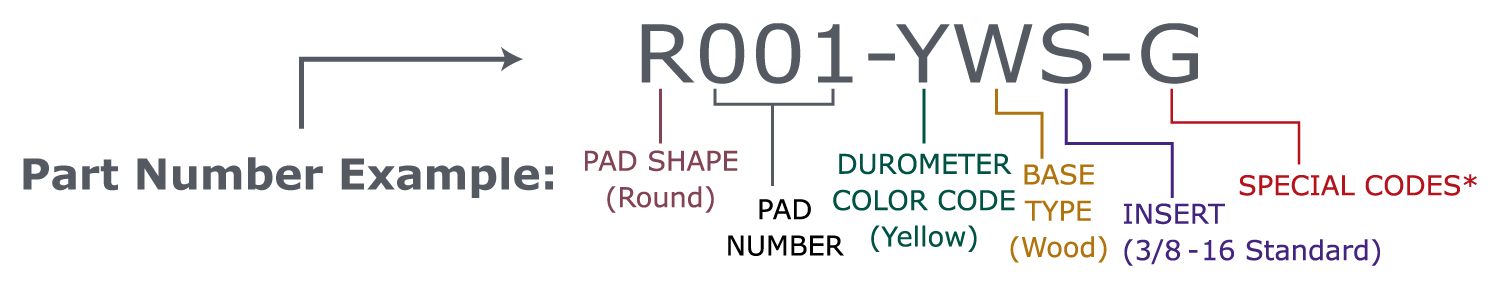

| 1) PAD SHAPE PREFIX CODE |

|---|

| An alpha character prefix defines shape of the pad |

| R = Round |

| S = Square |

| V = Vee or Stick |

| L = Loaf |

| C = Custom |

| 2) PAD NUMBER |

|---|

| We assign pad numbers consecutively as we create new molds. The pad number has no bearing on the size of the pads. |

| 3) DUROMETER COLOR CODE: | |||||

|---|---|---|---|---|---|

| All bases are color coded to designate durometer | |||||

| DuraProTM | DuraLiteTM | Stat-XTM | PrintzTM | Color Code | Durometer (00) |

| * | * | * | * | R=Red | 60-65 |

| * | * | * | * | Y=Yellow | 50-55 |

| * | * | * | * | G=Green | 40-45 |

| * | * | * | * | B=Blue | 30-35 |

| * | * | * | * | O=Orange | 20-25 |

| 4) BASE TYPE CODE |

|---|

| All bases are available in five configurations. |

| A = .250” Aluminum |

| B = .500” Aluminum |

| C = .375” Aluminum |

| W = Wood |

| X = Thin Wood |

| 5) INSERT CODE: |

|---|

| Threaded Insert or Tapped in Aluminum |

| N = No Insert |

| M = Metric (6 x .1mm course) |

| S = Standard (3/8" - 16) |

| T = Tapped in Aluminum (10-32) |

| Q = Quarter / Twenty (1/4" 20) |

| 6) SPECIAL CODES: | |||||

|---|---|---|---|---|---|

| G = High Gloss surface | |||||

| P = Our PrintzTM formulation (purple silicone) | |||||

| X = Our Stat-XTM formulation (green silicone) | |||||

| Note: There is no special etension for our Dura Pro series (red silicone) | |||||

If you do not know which pad(s) will fit your needs we will assist you in selecting the proper pad shape for your application. Please call our customer service department, but before you call we need the following information:

Machine type and model number

Inkwell and/ or cliché dimensions

Size and description of the part to be printed

Substrate material type

Part drawing (if possible) or please send us sample parts

Description of texture (if any) on the parts

Copy of artwork

One of the most frequently asked questions in the early stages of learning the do's and don'ts of the pad printing process is figuring out what pad to use for the part you are printing on.