Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

The INO A6 is a high-precision, high-throughput sheet-fed screen printing machine designed for industrial-scale heat transfer production, 3D decals, luxury packaging, and textile graphics. Designed and built in Europe, the A6 is available in North America through Deco Technology Group, a trusted technical partner offering installation, training, and ongoing support.

With speeds up to 800 sheets per hour and registration repeatability of ±30 µm, the A6 features camera-guided alignment, automated sheet handling, and seamless integration with drying, stacking, and powder systems. Its hybrid-ready design supports short runs, long runs, and personalized transfer production with minimal setup and unmatched consistency.

The INO HT Line, built around the high-performance PRINT A6 screen printing engine, merges the durability of traditional screen printing with the flexibility of modern digital workflows. This hybrid approach gives manufacturers the ability to handle short runs, long runs, and fully customized jobs—all with fast setup, consistent quality, and minimal operator intervention.

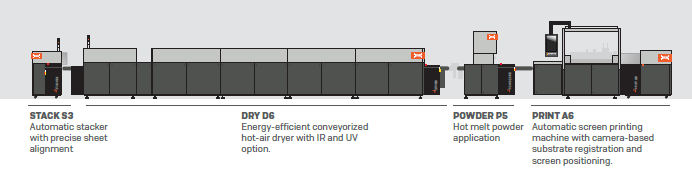

Designed for full-line automation, the A6 integrates seamlessly with:

Together, these modules create a fully automated, closed-loop production line tailored for high-quality textile heat transfers and other demanding sheet-fed screen printing applications.

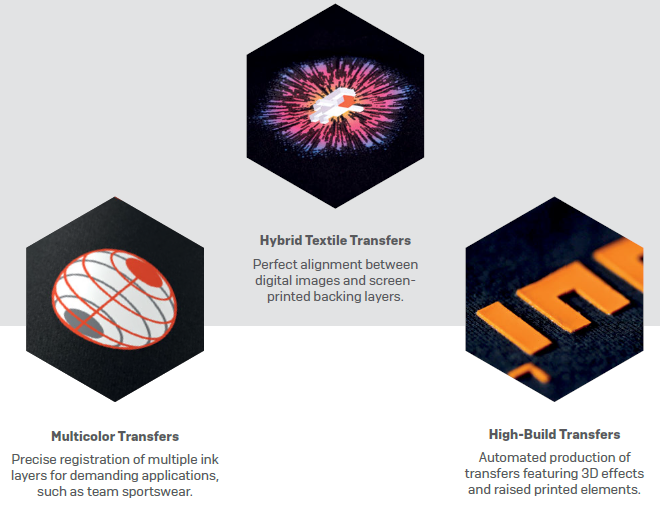

The INO A6 supports a wide range of advanced heat transfer applications—combining speed, precision, and automation for consistent, high-quality output. Whether you're producing hybrid digital/screen transfers, bold multicolor designs, or raised-effect graphics, the A6 delivers unmatched registration accuracy and repeatability.

These capabilities make the INO A6 the go-to platform for heat transfer decorators looking to scale production while maintaining top-tier print quality.

The INO A6 is designed to streamline high-volume production with advanced automation, intelligent controls, and ultra-precise screen alignment. Whether you're producing heat transfers, decals, or specialty graphics, the A6 ensures fast setups, reliable results, and minimal downtime.

Optimized Productivity

High Precision & Consistency

User-Friendly Operation

Optional Enhancements

The INO A6 is designed for manufacturers who require reliable, repeatable output across medium to high-volume production environments. Its camera-controlled registration, sheet-fed automation, and modular integration make it ideal for a wide range of advanced flatbed screen printing applications, including:

The A6 delivers proven value in industries where speed, alignment accuracy, and substrate flexibility are essential to productivity and profitability:

Contact Deco Tech today to learn how the INO A6 screen printing machine can deliver high-speed, high-precision results for your application. Whether you're printing multicolor textile transfers, secure ID cards, or premium packaging, our team offers expert consultation, application testing, and full support across North America.

Call us at (714) 639-DECO or email us at sales@decotechgroup.com

The INO A6 screen printing machine is a high-speed, sheet-fed flatbed press engineered for industrial-grade mass production. Below are the detailed technical specifications, including sheet handling, registration accuracy, substrate compatibility, and available format sizes.

| Technical Data | INO A6 |

|---|---|

| Machine Type: | Automatic sheet-fed flatbed screen printer |

| Material Handling: | Fully automated substrate manipulation |

| Max Production Speed: | Up to 800 sheets per hour |

| Substrate Compatibility: | Sheets from 75 µm to 600 µm thickness |

| Registration Accuracy: | ±30 µm with camera-controlled auto-registration |

| Print Length Correction: | Integrated for dimensional consistency |

| Control Interface: | Touchscreen HMI with intuitive software logic |

| Smart Connectivity: | Optional Industry 4.0 data protocol |

| Optional Features: |

|

| Repeatability: | ±30 µm |

| Sheet / Screen Sizes: |

|