Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Precision Powder Coating System for Hot Stamping Films, Heat Transfers & Industrial Graphics

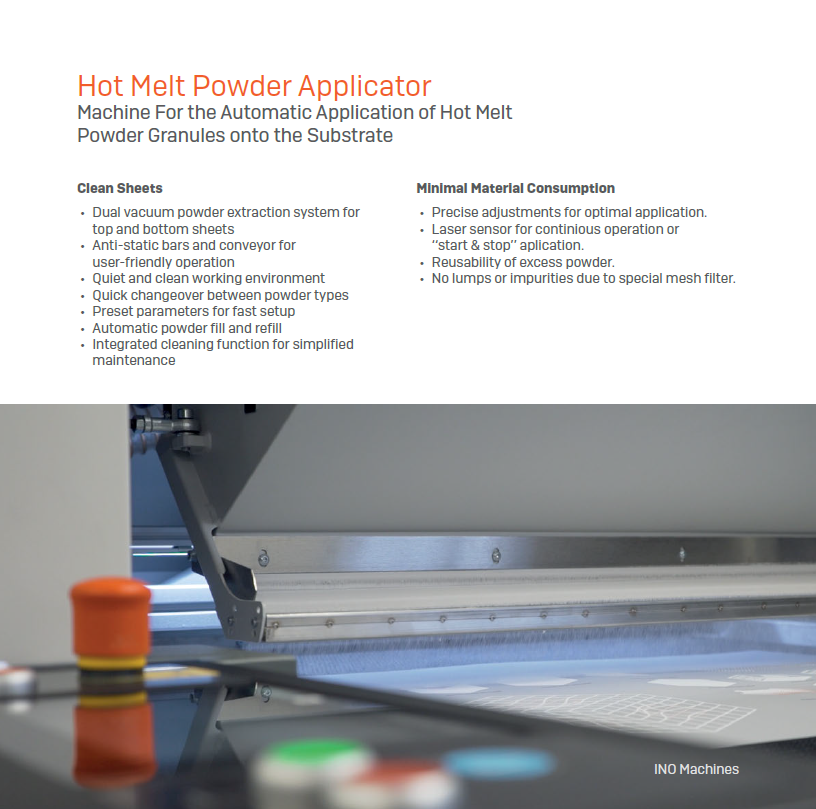

The INO Powder P5 is an advanced hot melt powder applicator designed for the automated coating of powdered adhesive onto flat substrates, enabling high-speed, uniform application for a wide range of industrial and textile printing applications. Whether you're working with hot stamping foils, DTF graphics, heat transfer films, or industrial screen-printed parts, the Powder P5 ensures maximum coverage accuracy, reusability, and minimal waste—all within a clean, efficient, and operator-friendly footprint.

With built-in vacuum extraction, anti-static conveyors, and mesh filtration, the Powder P5 delivers next-level precision for thermoplastic powder dispensing in digitally integrated workflows. It’s engineered for cleanroom-ready environments and supports high-volume production with minimal maintenance.

The Powder P5 includes a range of features that streamline the powder coating process and ensure consistent, defect-free results:

Powder waste is one of the greatest cost burdens in adhesive transfer applications. The Powder P5 minimizes consumption while maximizing effectiveness:

Whether you're coating substrates for textile graphics, technical fabrics, or printed electronics, the Powder P5 integrates seamlessly with other INO systems (screen printers, dryers, stackers) and is compatible with most powder types used in:

The Powder P5 is trusted by production facilities across the world to deliver consistent powder application for:

The INO Powder P5 is used to automatically apply powdered adhesive coatings onto substrates as part of a transfer printing or lamination process. This includes:

Streamline your screen printing workflow with the INO Powder P5 — the ideal automated solution for applying hot melt powder to heat transfer films, DTF sheets, textile graphics, and specialty substrates. Designed for high-precision powder distribution with anti-static handling and minimal waste, this powder applicator integrates seamlessly into industrial printing and heat transfer production lines.

Whether you’re working in DTF printing, hot stamping, fabric decoration, or heat transfer film manufacturing, the Powder P5 delivers consistent coverage, simplified changeovers, and optimized material usage — all while reducing labor and increasing output.

Contact Deco Tech today for pricing, lead times, or integration support.

Call us at (714) 639-DECO or email sales@decotechgroup.com to speak with our application experts.