Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Automated Sheet Stacking System with Precision Alignment for Screen Printing, Heat Transfers, Electronics, and Industrial Graphics

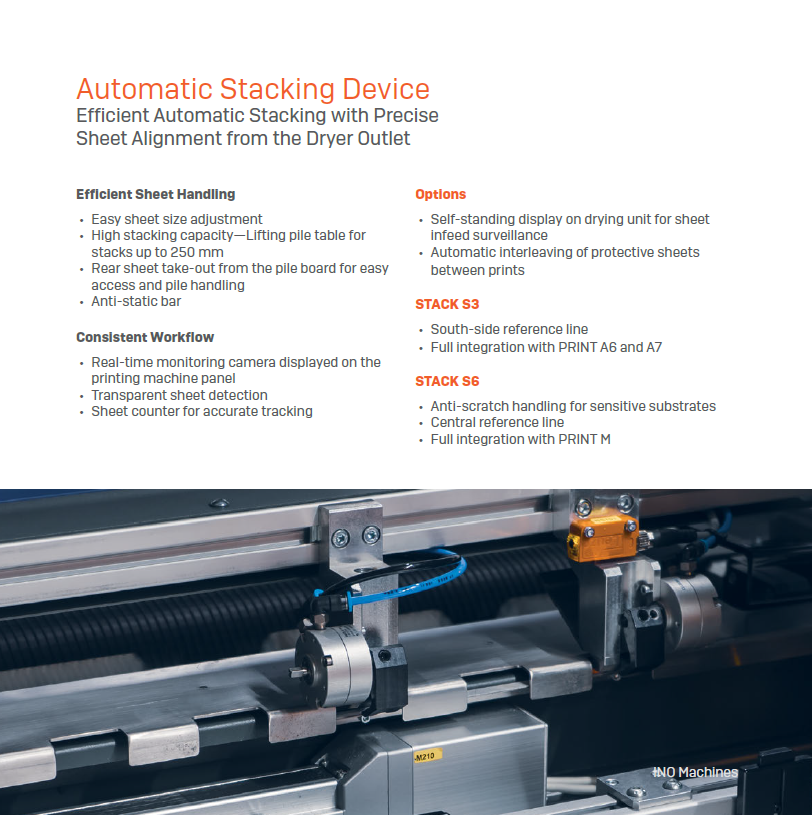

The INO STACK S is a fully automatic sheet stacking solution designed for seamless integration with conveyor dryers and screen printing systems. Ideal for printed electronics, industrial graphics, and heat transfer workflows, this high-capacity unit ensures fast, damage-free stacking of delicate or rigid substrates with minimal operator involvement.

Whether installed after a dryer or printer, the STACK S system delivers consistently aligned stacks, transparent sheet detection, and high throughput without bottlenecks—making it a crucial component in automated print production.

Powder waste is one of the greatest cost burdens in adhesive transfer applications. The Powder P5 minimizes consumption while maximizing effectiveness:

The STACK S ensures clean, controlled sheet handling at the end of each production cycle, whether placed after a drying module or printing press. It minimizes misalignment, prevents substrate damage, and eliminates the need for manual collection in continuous production environments.

From screen printed capacitive films to complex multilayer industrial graphics, the INO STACK S ensures that your sheets are stacked with precision, protection, and speed. When paired with INO’s dryers, printers, and feeders, it becomes a key component in a robust, fully automated workflow.

Contact Deco Tech today to learn how the STACK S can simplify your post-processing and boost overall production efficiency.

Call us at (714) 639-DECO or email sales@decotechgroup.com to speak with our application experts.