Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

The Swiss-built ecoCLEANER 500 NTD is a fully automated, water-based cleaning system specifically designed for pad printing components such as ink cups, clichés, doctor blades, and accessories. It eliminates the need for harsh solvents, reduces manual labor, and ensures safe and consistent cleaning results.

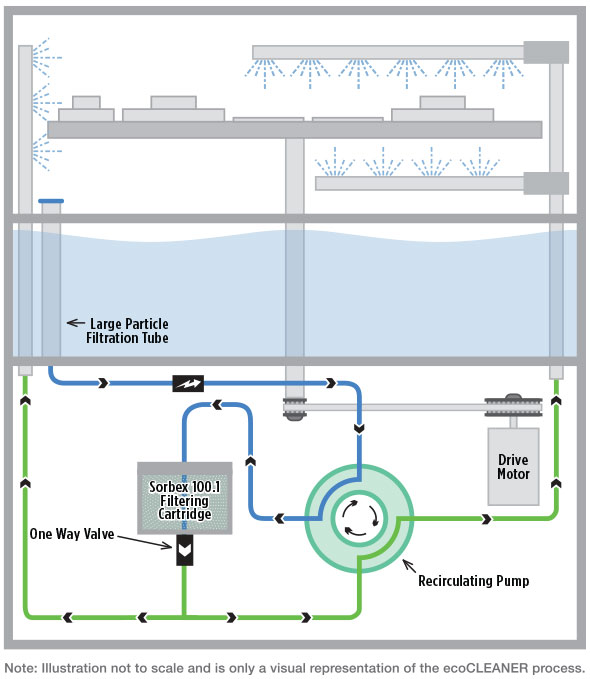

The Swiss-built ecoCLEANER 500 NTD is a water-based pad printing parts cleaner designed for ink cups, clichés, and accessories. This automatic ink cup cleaner reduces manual labor and ensures thorough cleaning using non-hazardous, reusable cleaning agents. Load your parts into the Eco-friendly pad printing parts cleaner and press start, and the ecoCLEANER uses high-pressure jets to remove pad printing ink effectively. With non-hazardous ink remover Cleanax 200.1 cleaning solution and Sorbex 100.1 ink filtration filters, waste ink is safely separated and filtered for reuse, minimizing costs and ensuring environmentally friendly disposal.

No harmful chemicals or strong odors

Automatic ink cup cleaning with high-pressure jets

Uses Cleanax 200.1 – a reusable, water-based cleaning agent

Safe and compliant ink waste separation and recycling

Designed for solvent-based ink removal

Handles hardened epoxy inks with programmable multi-cycle cleaning

The ecoCLEANER uses the Cleanax 200.1 solution to remove pad printing ink from all parts efficiently. Custom holders are available to accommodate specialized parts. Even hardened epoxy inks can be removed with additional washing cycles—extending the life of your components and reducing replacements.

During each cleaning cycle, Cleanax 200.1 is filtered and regenerated using the Sorbex 100.1 filter medium, making the cleaning agent reusable across multiple cycles. Cleaning programs can be customized from 5 to 15 minutes to match your workflow. This significantly reduces cleaning time, chemical usage, and operational cost compared to traditional solvent-based systems.

Switching to a water-based cleaning system is more than just an environmental upgrade—it’s a smart operational decision. The ecoCLEANER 500 NTD delivers Swiss-engineered reliability, reduced labor input, and consistent cleaning results for your pad printing components. With reusable cleaning agents, safe ink separation, and minimal downtime, it’s the modern solution for shops focused on quality, compliance, and efficiency.

Whether you're cleaning ink cups, clichés, or epoxy-covered parts, the ecoCLEANER provides a safer, cleaner, and more cost-effective alternative to traditional solvent systems.

📞 Call the experts at Deco Tech Group today at (714) 639-DECO to learn how the ecoCLEANER 500 NTD can transform your cleaning process and improve your production environment.

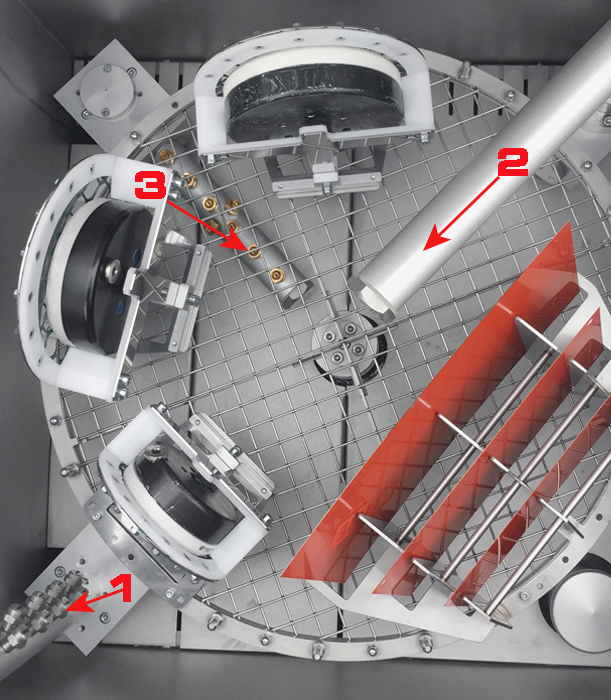

Three spray wands and a rotating basket ensure that parts are properly cleaned.

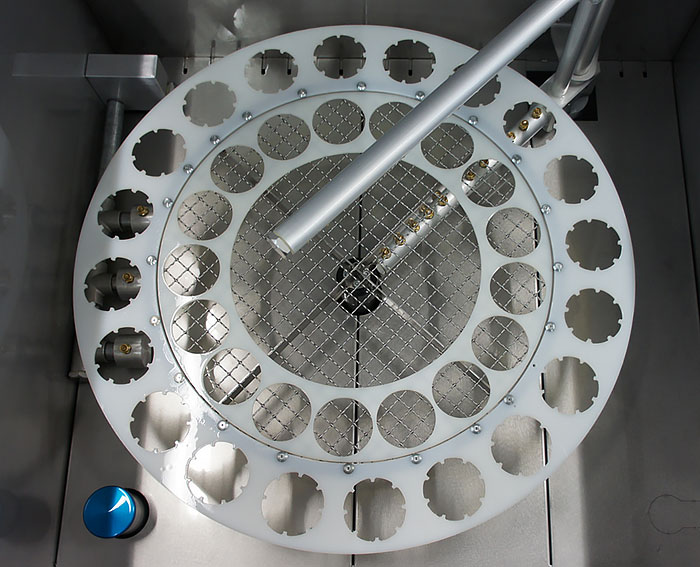

Optional ink cup holders are available in many configurations.

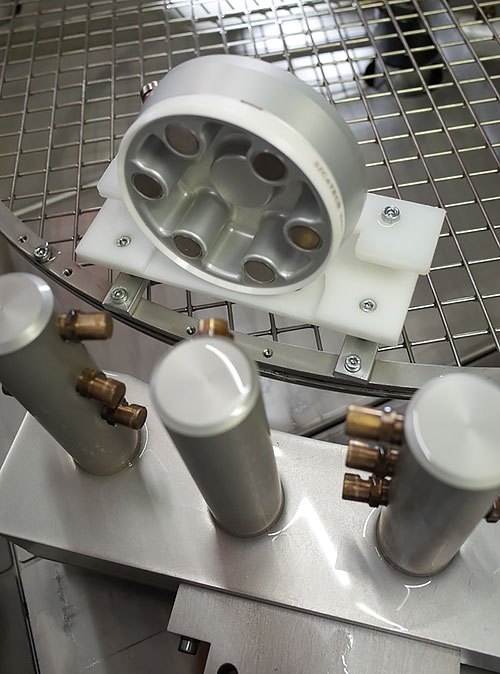

Shown with special nozzles for Tampoprint™ ink cups.

Optional side spray nozzles

Custom cup holders are available

Top loading adsorber cartridge

Heavy duty hinges

| Technical Data | ecoCLEANER 500 NTD |

|---|---|

| Dimension basket (Diameter): | 518mm |

| Dimension basket (Height): | 200mm |

| Filling ink removing agent: | 70 Liters |

| Electrical connection: | 230V / 50Hz (L+N_PE) |

| Power: | 1.2 kW |

| Air connection: | 5 bar |

| Cleaning time: | 5 - 15 minutes |

| Weight (without removing agent) | 423lbs (192 kg) |

| Machine Dimensions (LxWxH) | 640 x 924 x 1,097mm ( 26.37" x 36.37" x 43.18") |

Machine Type: Eco-Friendly Ink Cup & Cliché Cleaning System

Manufacturer: Osmeco

Origin: Made in Switzerland