Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

The German precision made RKS squeegee blades precision designed for all screen printing systems

German-Made RKS Squeegee Blades for Precision Screen Printing

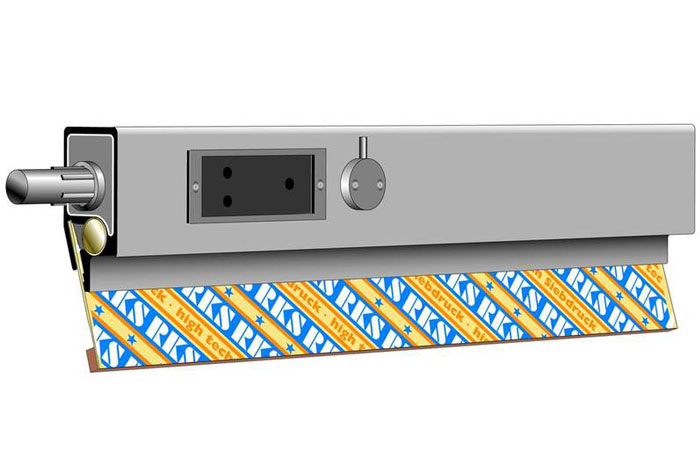

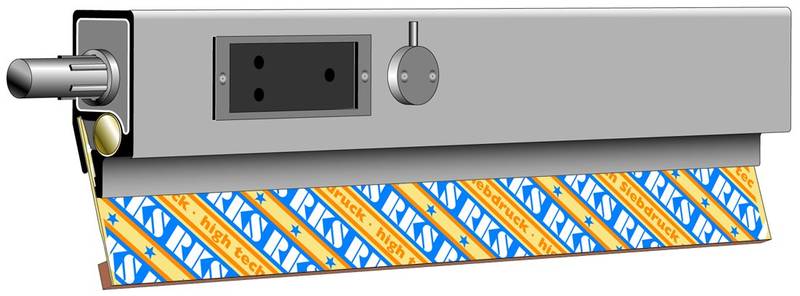

RKS squeegee blades—engineered and manufactured in Rösrath, Germany—are trusted by top-tier screen printing operations worldwide. These precision blades are the preferred choice for printers who demand the highest standards in quality, performance, and consistency. RKS is ISO 9001 certified, and their advanced manufacturing facility ensures exceptional process control and repeatability.

While others have attempted to imitate the RKS design, none have matched the quality, durability, or precision that RKS delivers. For printers striving to maintain world-class output, RKS squeegees remain the benchmark in high-performance screen printing technology.

RKS System Squeegee Blades — Engineered for Precision and Repeatability

RKS System Squeegee blades are engineered with a unique dual-component construction to ensure unmatched printing consistency and performance. Each blade is comprised of:

The RKS System Squeegee blade is engineered to achieve absolute parallel printing precision. Watch the video above—you’ll see flawless ink laydown without a single wavy streak, even at high speeds.

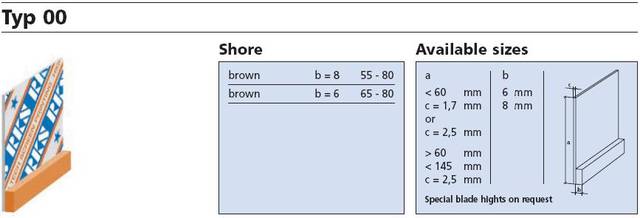

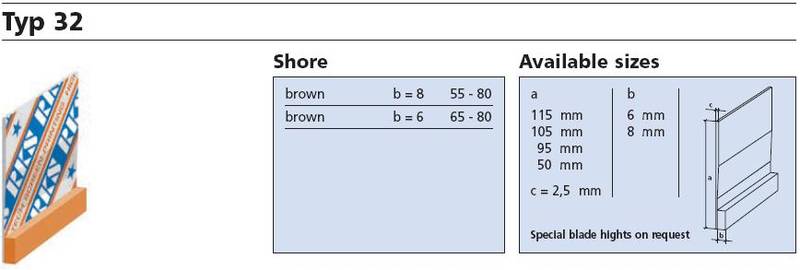

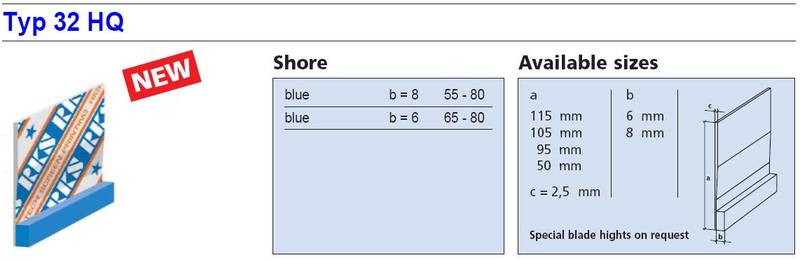

Available Sizes and Durometers

RKS System Squeegees are available in:

Note: The 55° shore material is only offered in 8 mm thickness.

The different strip thicknesses allow for fine-tuned control of squeegee hardness. For example, due to the fiberglass backer, a 65° shore / 6 mm blade will perform stiffer than a 65° shore / 8 mm blade—allowing printers to optimize squeegee stiffness for their specific application.

RKS System Squeegees are supplied with durometer ranges from 55 to 80 shore. RKS has managed to apply the latest technological advances to achieve the best possible physical strength characteristics and high resistance to inks & solvents, delivering optimal on-press performance. This means that the service life of an RKS System Squeegee blade reaches levels believed to be impossible up until this superior squeegee blade was developed.

It is a fact that RKS squeegee blades require less application pressure than a conventional rubber squeegee blades. This means that the screens and stencil image is subject to less wear & tear, leading to a noticeable increase in screen life and squeegee life. Less pressure equals less mechanical stress (deflection) for the entire screen printing machine.

* Maximum production length approx 2800mm;

* Maximum production length approx 2800mm;

* Maximum production length approx 2600mm;

If you're a seasoned screen printing operator, you already know: traditional rubber squeegees often fail to deliver the consistency, repeatability, and standardization required for high-quality production.

Over time, traditional polyurethane squeegees are permanently affected by solvents and ink additives. These factors cause:

These combined variables make traditional squeegees unreliable, turning your printing process into a trial-and-error operation that requires constant adjustments and oversight from highly skilled operators.

RKS System Squeegees solve these challenges with engineered materials, stable construction, and unmatched repeatability:

Ready to break free from inconsistent printing? Try an RKS System Squeegee and experience the difference for yourself.

Ask us about our free sampling program—we’ll help you test and see firsthand why printers worldwide are making the switch to RKS.

1) For Coarse or Textured Surfaces:

When printing on rough or uneven substrates, coarse mesh fabrics, or requiring heavy ink laydown, we recommend using 8 mm / 65° shore blades. This configuration offers ideal flexibility and deposit volume for these challenging applications.

2) For Fine Detail and Tight Registration:

For precise printing applications involving fine text, tight registration, or smooth substrates, the 6 mm / 75° shore blades are preferred. This setup delivers enhanced edge definition and minimal dot gain.

3) For Greater Flexibility Needs:

If the standard RKS System Squeegee feels too rigid for your application, consider switching to the Carbon S squeegee blades. These blades offer increased flexibility while maintaining excellent print quality.

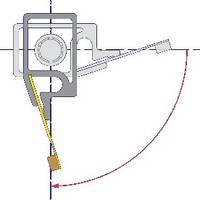

4) Optimize the Printing Angle:

The standard RKS blade angle is 18° from the vertical (0° reference). To achieve a higher ink deposit, the angle can be increased up to 20° maximum. Always ensure angle adjustments are consistent across the blade for optimal results.

The RKS squeegee is a precision tool and as such, it must be handled properly. Compared with a traditional rubber squeegee, it requires less contact pressure for the same printing process, so start with minimal pressure and work your way up slowly until you get a quality print. Also ensure that the squeegee blade is parallel with the printed substrate, vacuum table or the impression cylinder (for roll to roll screen printing applications). If you change-out to a new RKS blade (of the same height), then you don’t need any adjustments or position corrections, you will get the same printing results! Never cycle the squeegee without ink in the screen as this will heat up the screen and blade material and the precision printing edge will break down or break off immediately. If that happens the you’ve got to stop production and head to the squeegee grinder and now your screen press is at a standstill. Also "non-stop printing" will cause damage to the service life of all polyurethane materials. Therefore we recommend that you change-out the squeegee after 5 to 6 hours when using solvent based inks and after 4 hours when UV cured inks.

So clean the RKS System Squeegee blade thoroughly after it comes off the press and let it “exhale” or relax for at least 12 - 24 hours before running that blade again. If you follow these guidelines your RKS System Squeegee will always work well and provide a constant tolerance range. Also by relaxing your blades there is no danger that the printing edge will break off, like it would if the blade was run too long and was swollen by the ink solvents or other volatile ink components. A little preventative maintenance goes a long way in increasing your blade life.

The RKS squeegee is a precision tool and as such, it must be handled properly. Compared with a traditional rubber squeegee, it requires less contact pressure for the same printing process, so start with minimal pressure and work your way up slowly until you get a quality print. Also ensure that the squeegee blade is parallel with the printed substrate, vacuum table or the impression cylinder (for roll to roll screen printing applications). If you change-out to a new RKS blade (of the same height), then you don’t need any adjustments or position corrections, you will get the same printing results! Never cycle the squeegee without ink in the screen as this will heat up the screen and blade material and the precision printing edge will break down or break off immediately. If that happens the you’ve got to stop production and head to the squeegee grinder and now your screen press is at a standstill. Also "non-stop printing" will cause damage to the service life of all polyurethane materials. Therefore we recommend that you change-out the squeegee after 5 to 6 hours when using solvent based inks and after 4 hours when UV cured inks.

So clean the RKS System Squeegee blade thoroughly after it comes off the press and let it “exhale” or relax for at least 12 - 24 hours before running that blade again. If you follow these guidelines your RKS System Squeegee will always work well and provide a constant tolerance range. Also by relaxing your blades there is no danger that the printing edge will break off, like it would if the blade was run too long and was swollen by the ink solvents or other volatile ink components. A little preventative maintenance goes a long way in increasing your blade life.