Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

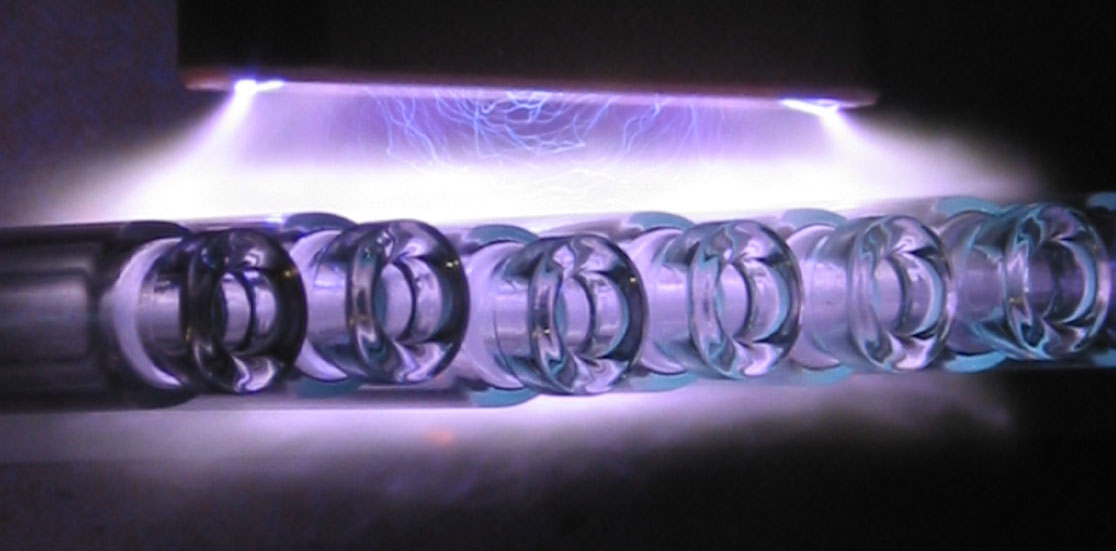

As the exclusive North American distributor for SICA TECH of Denmark, Deco Tech proudly supplies and supports their industry-leading low-frequency corona discharge systems. Engineered for complex 3D plastic parts, tubing extrusions, and difficult-to-treat substrates, SICA TECH’s corona treatment equipment is trusted by leaders in medical device manufacturing, automotive, pharmaceutical, consumer goods, and injection molding industries.

Corona pre-treatment—also known as corona discharge treatment—is a high-efficiency method for increasing the surface energy (dyne level) of plastics, foams, and low-surface-energy materials. This vital surface preparation step ensures proper adhesion of inks, adhesives, coatings, and functional layers during downstream printing or bonding operations.

SICA TECH systems deliver uniform, reliable treatment even on curved, contoured, or irregular 3D parts.

Many plastics and synthetic materials—such as polypropylene (PP), polyethylene (PE), TPEs, and nylon—have naturally low surface energy, which makes it difficult for inks, adhesives, or coatings to bond effectively. Without pre-treatment, prints may smear, adhesives may peel, and coatings may delaminate over time.

Corona treatment solves this problem by applying a high-voltage electrical discharge to the material’s surface. This process temporarily increases the surface energy (dyne level) of the material, improving wettability and allowing inks and adhesives to chemically bond to the surface more reliably.

✅ Improved Ink Adhesion – Ensure consistent print quality on low-dyne substrates

✅ Stronger Bonding for Adhesives & Coatings – Critical in medical, automotive & packaging applications

✅ More Reliable Decorating & Assembly – Reduce reject rates and boost production yield

✅ Safe & Chemical-Free – Uses air and electricity, no solvents or priming agents

✅ Compatible with 3D Parts – Treat contoured, molded, and irregularly shaped parts effectively

Corona surface treatment is essential for preparing a wide variety of materials that are naturally resistant to inks, adhesives, and coatings. SICA TECH’s low-frequency corona systems—distributed and supported by Deco Tech—are engineered for industrial performance across a broad range of applications and substrates:

Ideal for decorating and bonding on molded parts made from polypropylene (PP), polyethylene (PE), ABS, and other low-surface-energy resins. Frequently used in automotive, consumer goods, and medical device housings.

Enables permanent adhesion of graduation marks, coatings, or labels on catheters, vials, surgical instruments, diagnostic components, and other critical medical-grade plastics with chemically inert surfaces.

Used for IV lines, airflow tubing, and industrial hoses. Corona treatment enhances the bond between tubing and printed instructions, color codes, or adhesive layers for improved performance and traceability.

Corona discharge prepares foam inserts, pads, and coated foam packaging for printing or lamination with other materials such as films, labels, or seals. Often used in electronics, cosmetics, and protective case manufacturing.

Perfect for coated films, UV-cured surfaces, Teflon-like materials, and other challenging substrates that resist wetting. Corona treatment opens the surface for clear coatings, ink adhesion, or adhesive bonding—even on engineered or exotic polymers.

More than a distributor, Deco Tech offers complete turnkey corona pre-treatment systems tailored to your workflow. We design and integrate SICA TECH LF-Series units into:

To support a safe and compliant operation, we also supply ozone filtration systems and carbon scrubbers to neutralize ozone emissions generated during corona discharge.

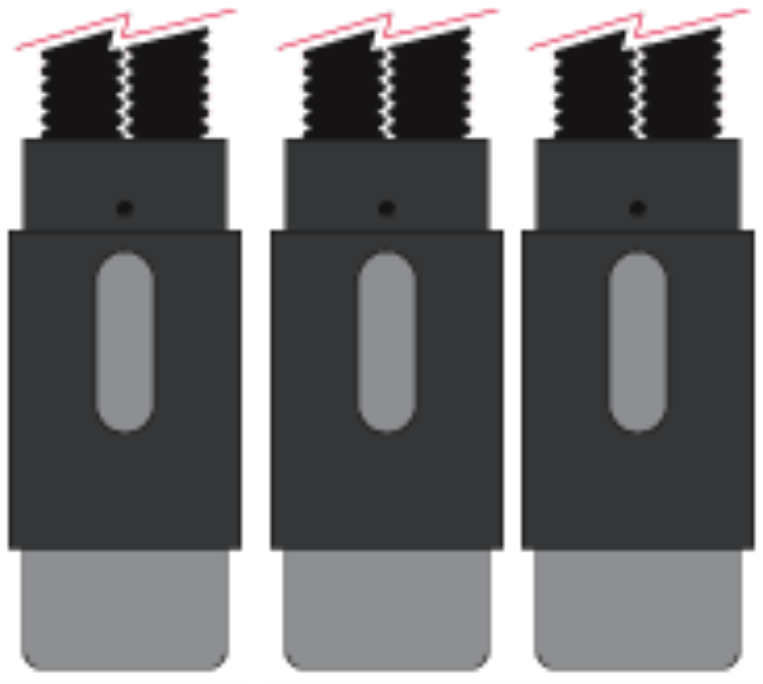

LF-1, LF-2, LF-3, and LF-4 models are available, featuring 1 to 4 ceramic treating heads and linear coverage up to 380mm. All models include quick-change electrodes, air hose kits, and are compatible with automation integration. Power outputs range from 800W to 3,200W depending on model size and number of treating heads.

Contact Deco Tech today at (714) 639-DECO or email us at sales@decotechgroup.com to discuss the best SICA TECH LF-Series system for your parts, substrates, and production needs.

| Technical Data | SICATECH LF-1 |

|---|---|

| Stationary Treating area: | Single head 65 x 95mm |

| Power output: | 800 watts |

| Dimension: | 410 x 410 x 230mm |

| Weight (Net): | 25 Kg. |

| Input Voltage: | 115 or 230V switchable |

| Technical Data | SICATECH LF-2 |

|---|---|

| Stationary Treating area: | 2 Heads: 65 x 95mm |

| Power output: | 800 watts x 2 |

| Dimension: | 410 x 410 x 230mm |

| Weight (Net): | 40 Kg. |

| Input Voltage: | 115 or 230V switchable |

| Linear Treating width*: | Approx. 130 to 190mm |

* Approx. ± range is application specific on linear conveyor systems

| Technical Data | SICATECH LF-3 |

|---|---|

| Stationary Treating area: | 3 Heads: 65 x 95mm |

| Power output: | 800 watts x 3 |

| Dimension: | 820 x 480 x 250 mm |

| Weight (Net): | 65 Kg. |

| Input Voltage: | 230V |

| Linear Treating width*: | Approx. 195 to 285mm |

* Approx. ± range is application specific on linear conveyor systems

| Technical Data | SICATECH LF-4 |

|---|---|

| Stationary Treating area: | 4 Heads: 65 x 95mm |

| Power output: | 800 watts x 4 |

| Dimension: | 820 x 480 x 250 mm |

| Weight (Net): | 75 Kg. |

| Input Voltage: | 230V |

| Linear Treating width*: | Approx. 260 to 380mm |

* Approx. ± range is application specific on linear conveyor systems