Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

The OSMECO Swiss precision built ecoCLEANER MODEL 740 NTD is an earth friendly water based parts washing system for cleaning-up pad printing ink cups, clichés and accessories. With an ecoCLEANER in your plant you can say good-bye to the labor intensive, expensive and unenjoyable task of cleaning your ink cups by hand. Cleaning up

Cleaning ink cups is one of the most unpleasant, time-consuming, and often neglected tasks in pad printing production. Manual cleaning not only consumes valuable labor hours, but it also results in inconsistent and often incomplete cleaning—leading to premature wear of components and potential print defects.

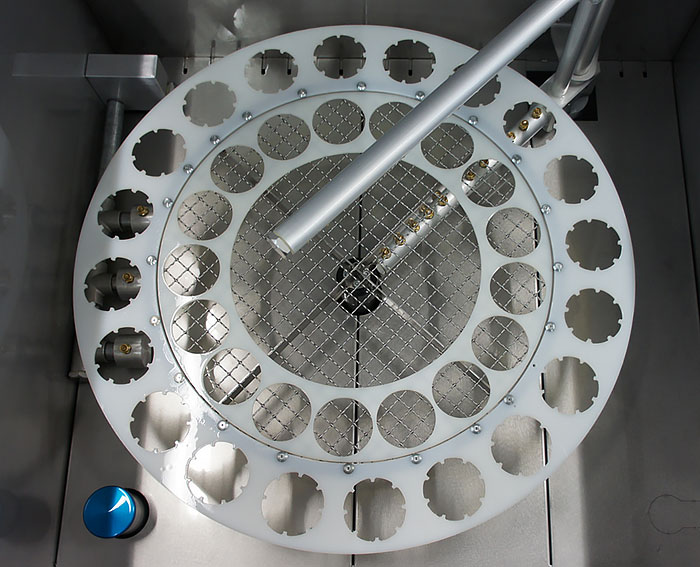

The Osmeco ecoCLEANER 740 NTD puts an end to this inefficiency with fully automated, high-performance cleaning. Designed specifically for pad printing accessories, this Swiss-built machine allows operators to simply load dirty ink cups, pad printing clichés, doctor blade assemblies, and other parts into the stainless steel basket, close the lid, press start—and walk away. The machine handles the rest.

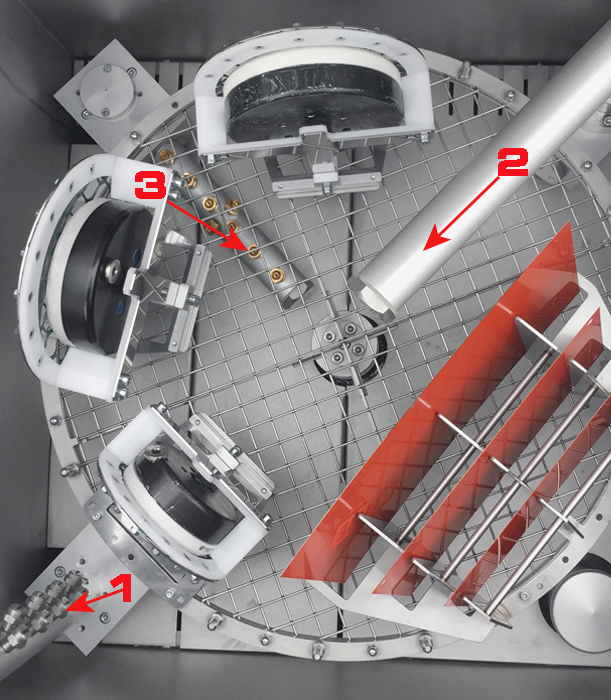

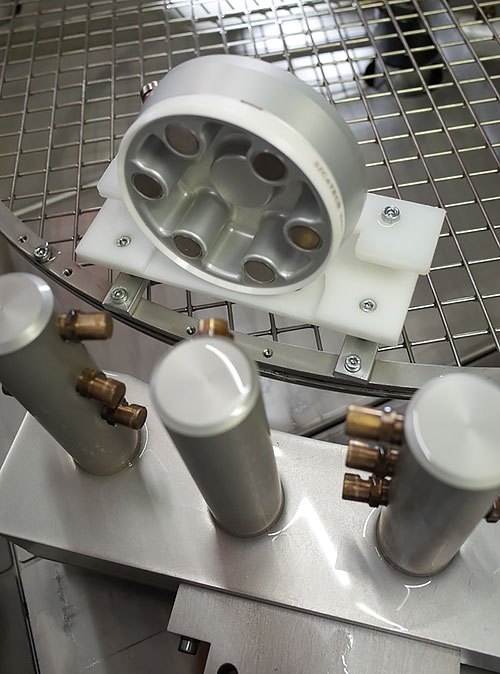

Using three powerful, high-pressure spray nozzles—strategically positioned at the top, bottom, and side—the ecoCLEANER delivers complete coverage to remove even the most stubborn ink residues. The basket rotates during the cycle, ensuring that every surface of every part is thoroughly cleaned, including recessed areas that are typically missed by manual methods.

At the core of the ecoCLEANER’s cleaning power is Cleanax 200.1, a non-hazardous, water-based cleaning solution specially formulated for pad printing inks. Whether you're using 1-component or 2-component solvent-based inks, UV/solvent hybrids, or even fully hardened epoxy inks, Cleanax 200.1 breaks them down effectively—often restoring “ruined” ink cups back to usable condition.

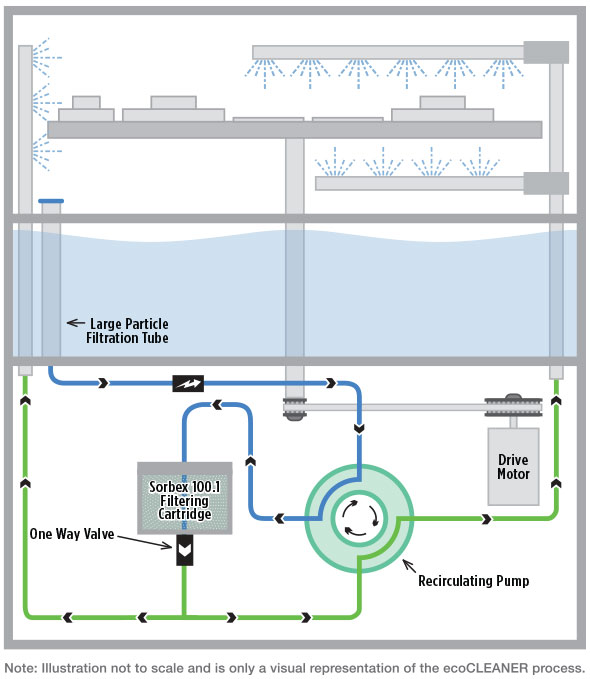

But it’s not just the cleaning agent that makes this system special—it’s the intelligent recycling and filtration system built into every ecoCLEANER unit. During operation, used Cleanax 200.1 is continuously filtered and rejuvenated through Sorbex 100.1, a natural, eco-friendly filtration medium that separates ink pigments, binders, and residues from the usable cleaning fluid. This closed-loop system reduces fluid replacement costs and minimizes environmental impact.

The result? Clean parts, lower waste, and dramatically reduced labor. Your ink cups, steel clichés, and delicate machine components come out spotless and ready for production—all with minimal supervision.

And best of all: the separated waste ink residue is dry, inert, and can be safely disposed of in most landfills as non-hazardous waste—as long as you are using inks compliant with North American safety standards.*

*Note: This statement of claim is made with the supposition that you as the user are utilizing commercially approved and safe pad printing inks that are manufactured within the safety standards and regulations for North American consumption/ usage. Please consult with your local environmental expert/ consultant and/or appropriate regulatory agencies to be certain of your compliance with all local, state and federal laws before disposing of your broken down ink particles into a landfill.

The ecoCLEANER is compatible with:

The Cleanax 200.1 ink remover is a non-hazardous, non-flammable cleaning agent formulated to tackle the toughest jobs in pad printing cleanup. Whether you're working with solvent-based or UV/solvent hybrid inks, Cleanax 200.1 effortlessly breaks down and removes stubborn residues from all key components — including ink cups, pad printing clichés, cliché holders, and doctor blade assemblies.

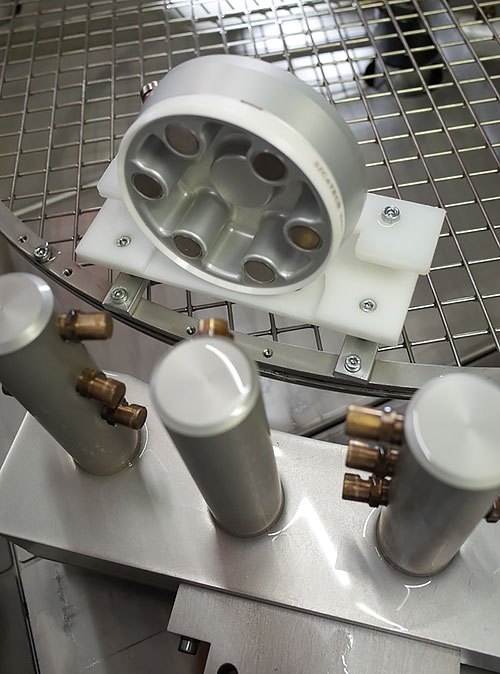

The OSMECO ecoCLEANER system pairs this powerful cleaning agent with a fully automated, high-pressure spray process that targets every angle of your parts. A rotating stainless-steel basket ensures even coverage, while three directional spray jets reach into the most difficult-to-clean areas. Even fully cured two-component epoxy inks can be stripped away with extended or repeated cycles — allowing you to reclaim expensive ink cups that would otherwise be scrapped.

Custom ink cup holders are also available for machines using lightweight plastic-bodied ink cups, ensuring secure placement and thorough cleaning regardless of your machine type.

The ecoCLEANER’s advanced natural filtration system continuously separates out the pigment, resin, and solvent components of used ink, using the science of surface tension for maximum cleaning efficiency. As Cleanax 200.1 circulates through the machine, it’s filtered and rejuvenated for repeated use — minimizing waste, reducing cleaning agent consumption, and keeping your equipment consistently clean and production-ready.

During each cleaning cycle, the ecoCLEANER continuously filters the used Cleanax 200.1 cleaning agent—removing broken-down ink components such as pigments, resins, and solvents—and recirculates the rejuvenated fluid back into the system. This closed-loop process, powered by the Sorbex 100.1 natural filter medium, significantly extends the usable life of the ink remover while reducing waste and operational costs.

Cleaning cycles can be programmed via the control panel in 10-, 20-, or 30-minute intervals (20 minutes is ideal for most applications). Unlike traditional solvent-based systems, the ecoCLEANER requires far less chemical replenishment, thanks to its efficient reclamation and recycling system.

Contact Deco Tech to learn how the Swiss-built ecoCLEANER 740 NTD can streamline your workflow, cut labor costs, and safely clean your ink cups, clichés, and accessories with water-based precision.

Call us at (714) 639-DECO or email us at sales@decotechgroup.com.

Three spray wands and a rotating basket ensure that parts are properly cleaned.

Optional ink cup holders are available in many configurations.

Shown with special nozzles for Tampoprint™ ink cups.

Optional side spray nozzles

Custom cup holders are available

Top loading adsorber cartridge

Heavy duty hinges

Custom cup holders are available

| Technical Data | ecoCLEANER 740 NTD |

|---|---|

| Dimension basket (Diameter): | 770mm |

| Dimension basket (Height): | 200mm |

| Filling ink removing agent: | 70 Liters |

| Electrical connection: | 230V / 50Hz (L+N_PE) |

| Power: | 1.2 kW |

| Air connection: | 5 bar |

| Cleaning time: | 5 - 15 minutes |

| Weight (without removing agent) | 527 lbs (239 kg) |

| Machine Dimensions (LxWxH) | 908 x 1,164 x 1,097mm ( 35.75" x 45.8" x 43.18") |

Machine Type: Eco-Friendly Ink Cup & Cliché Cleaning System

Manufacturer: Osmeco

Origin: Made in Switzerland