Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Pad printing is one of the most adaptable and widely used printing processes in industrial, promotional, and medical markets. While it excels at printing on uneven and 3D surfaces, there are a few limitations that should be understood when specifying this process for your product.

Pad printing is best suited for small to medium-sized graphics. The image size is typically limited by:

This makes pad printing less effective for large-format artwork or oversized products unless custom automation or multiple passes are used.

While multi-color pad printing is common, maintaining tight registration between colors can be more difficult than in digital or screen printing:

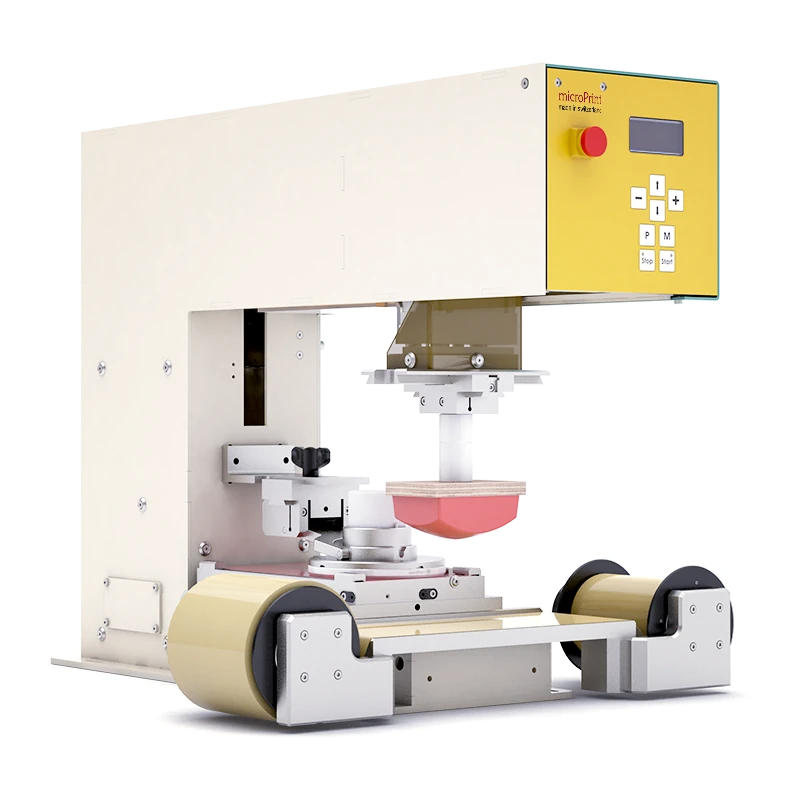

Swiss-made microPrint systems (available from Deco Tech) can help minimize these issues with servo-driven accuracy and programmable alignment systems.

Pad printing is typically used for solid spot colors and logos—not photographic images or gradients. This makes it less suitable for projects requiring:

However, sharp logos, icons, barcodes, and part numbers print beautifully with the right pad, ink, and pressure settings.

Some plastics like silicone, acetal (Delrin), or untreated polypropylene (PP) have low surface energy, making ink adhesion difficult. Without proper surface treatment (flame, corona, or plasma), prints may scratch off or fail adhesion tests.

At Deco Tech, we offer pre-treatment services and testing to maximize ink bonding on hard-to-print materials.

Although pad printing works well on 3D shapes, there are still restrictions:

In such cases, a custom pad shape or alternate method like screen or digital printing may be more appropriate.

Pad printing inks—especially 2-component or UV-curable types—may require:

We provide guidance on proper ink handling and curing options for production consistency.

You may want to consider screen or digital printing instead of pad printing when:

Call 714-639-DECO or email sales@decotechgroup.com to speak with a printing expert and discuss your application needs.