Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Our automated systems deliver faster cycle times, reduced downtime, and repeatable precision—freeing up operators and increasing daily output without sacrificing print quality. Ideal for scaling production efficiently.

Deco Tech automation slashes labor requirements and virtually eliminates scrap, with reject rates typically below 1%. Lower operating costs and faster ROI make our systems a smart long-term investment.

We don’t just install machines—we provide complete training, documentation, and technical support. Your team will have the tools and knowledge to run production independently with minimal disruption.

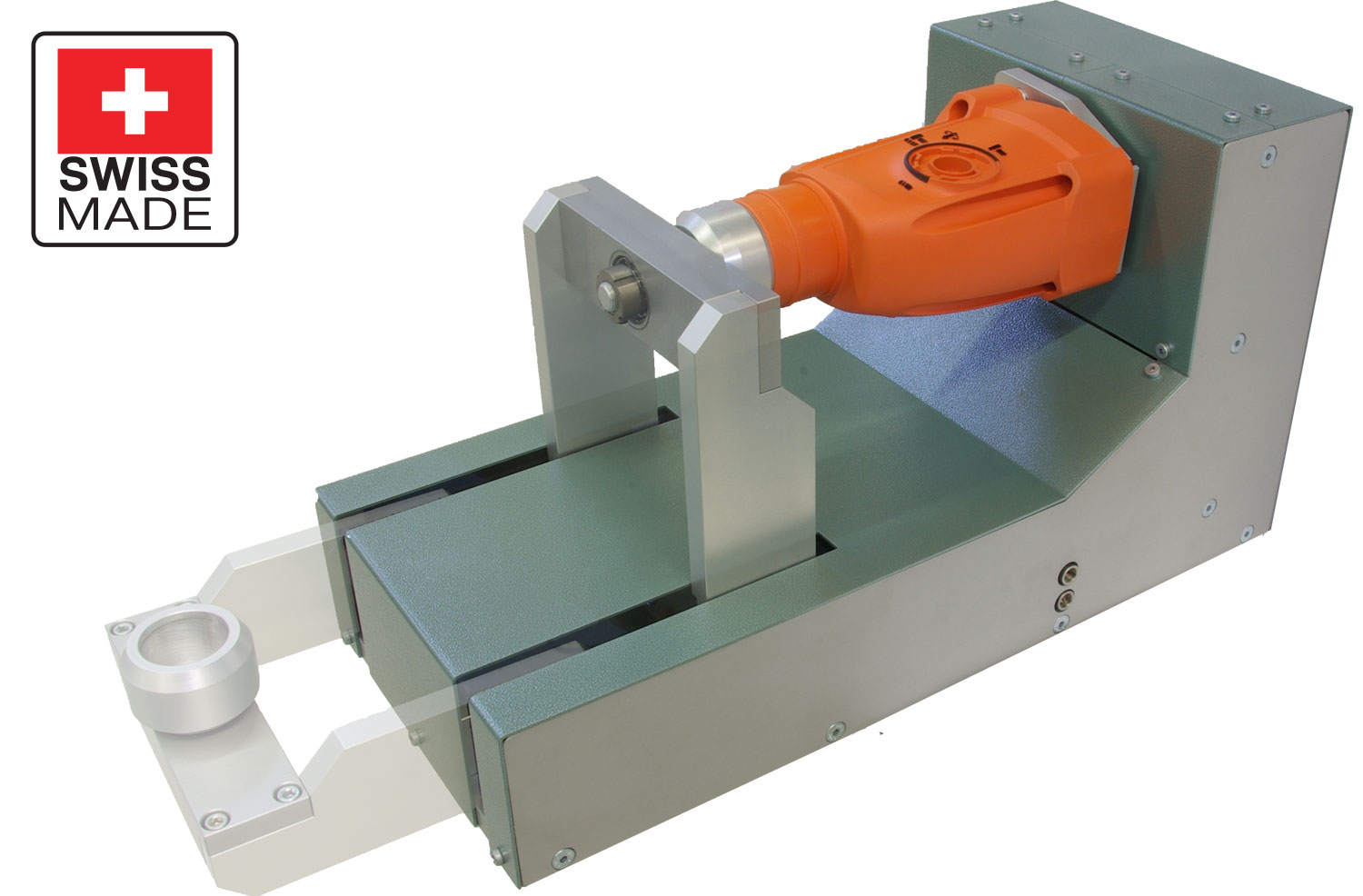

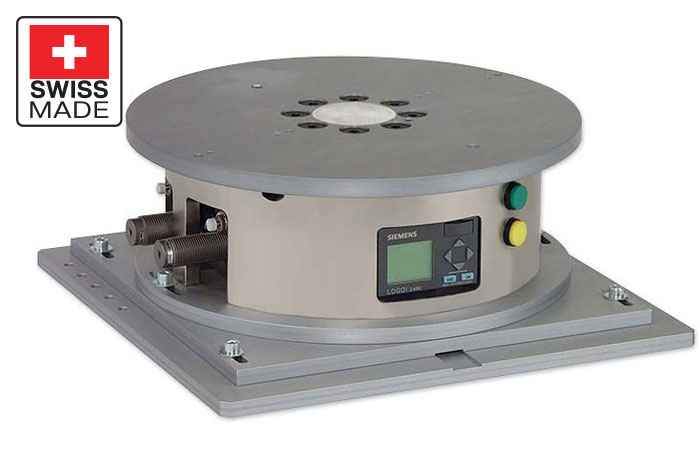

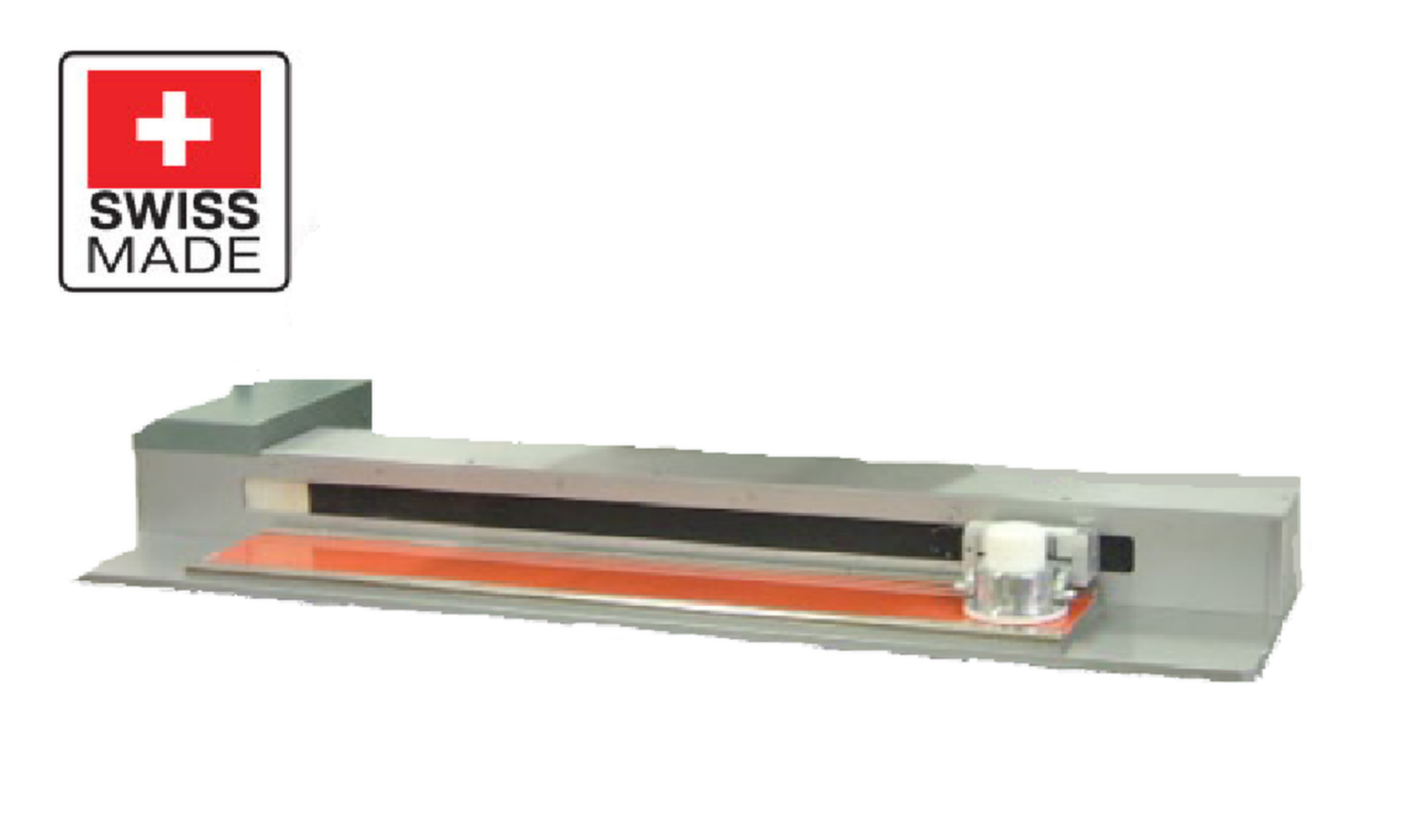

MicroPrint of Switzerland offers a comprehensive range of standard and custom automation accessories designed for seamless integration with pad printing machines. Our solutions include rotary table indexers, oval racetrack indexers, linear and pneumatic part or pad shuttles, pad actuators and lifters, multi-axis 3D robotic manipulators, and much more. As experts in pad printing automation, MicroPrint specializes in delivering custom turn-key solutions to meet your specific automation needs.

At Deco Tech we have extensive knowledge in a wide variety of markets

We work closely with you, and we help to clarify your precise needs & goals for the project. We always strive to provide the right pad printing automation solution based on your needs and budget and our goal is to meet or exceed your requirements & expectations. We listen carefully to your needs, wants, concerns and we take into account what your real-world experiences are with printing your product(s). Once we fully understand your needs, then we go about designing the right turn-key automated pad printing solution and we provide you with a system drawing and a formal quotation.

Our experts carefully review numerous topics including: