Speak to an Expert Today!

714-639-3326

sales@decotechgroup.com

Headquarters

1040 Segovia Circle

Placentia, CA 92870

Deco Tech is your trusted North American supplier of industrial pad printing machines, systems, and consumables — engineered for reliable, high-volume production.

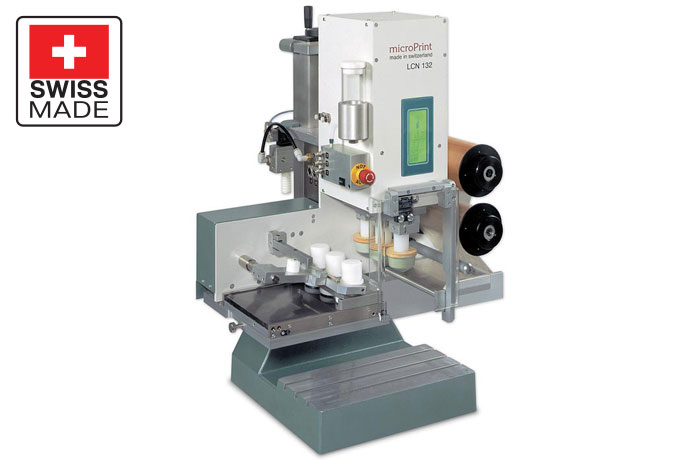

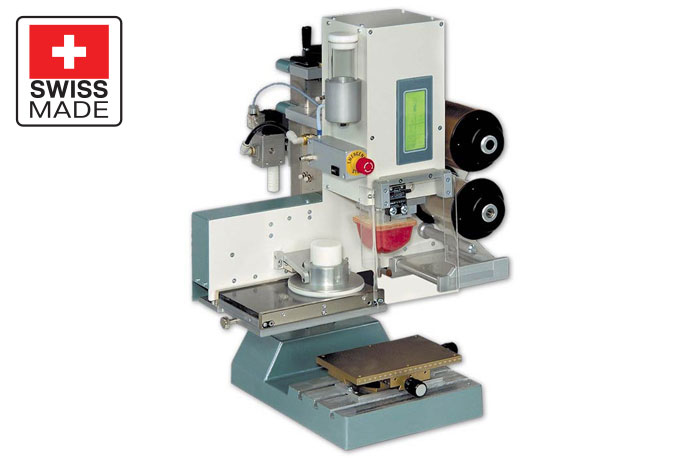

microPrint of Switzerland designs and manufactures precision pad printing machinery renowned for its exceptional quality, reliability, and innovation. Each system is built with advanced engineering and unique quality control features that take pad printing to a new level of performance and consistency.

microPrint pad transfer printers are equipped with industry-leading innovations such as automatic ink viscosity control, automatic pad cleaning systems, and user-friendly interfaces — all designed to improve print accuracy, reduce operator intervention, and increase production efficiency. These advanced features, combined with Swiss craftsmanship, make microPrint machines the benchmark in high-end pad printing technology.

The Deco Tech line of pad printing equipment is designed for small to mid-sized companies seeking reliable, cost-effective solutions without compromising on quality. These machines are well-suited for businesses that require consistent performance, flexible operation, and solid technical support — all at a competitive price point.

In addition to the equipment, we offer full technical support, operator training, and custom tooling tailored to your production needs. Our pad printing systems are backed by a comprehensive range of consumables, including high-quality inks, silicone pads, clichés (plates), and accessories — ensuring you have everything needed to run an efficient, dependable pad printing process.

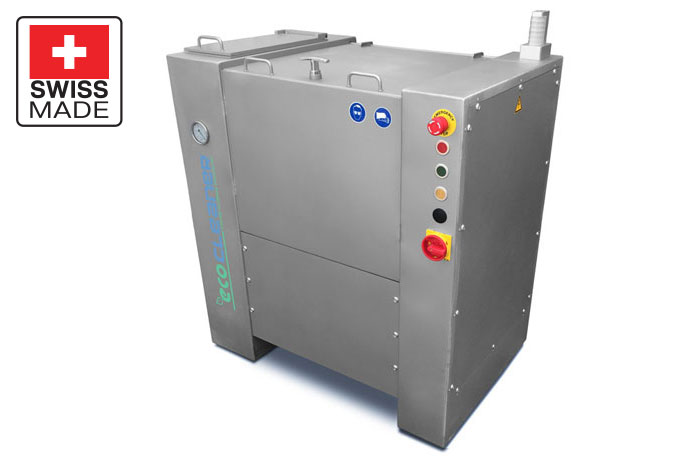

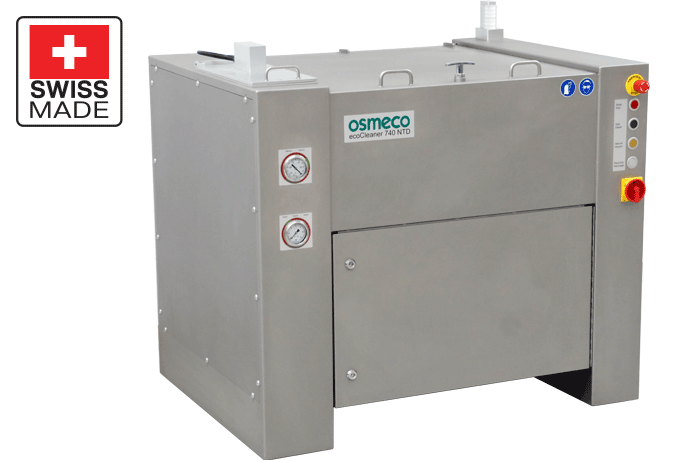

Our Swiss-made, eco-friendly pad printing cleaning systems are engineered for safe and effective cleaning of ink cups and pad printing plates (clichés). These systems use a water-based cleaning solution that is continuously filtered and recirculated — eliminating the need for frequent replacement of the cleaning agent and significantly reducing waste.

Designed for efficiency and long-term use, these units help maintain optimal print quality by keeping your tooling consistently clean. The system can also be configured to accommodate rotogravure and flexographic parts, making it a versatile solution for facilities handling multiple print technologies.

Deco Tech provides industry-leading automated pad printing machines engineered for high-volume, multi-color, and precision printing applications. As the exclusive North American partner of microPrint Switzerland, we offer custom pad transfer printing automation designed for medical devices, automotive components, promotional goods, and plastic injection-molded parts.

Our pad printing automation systems feature:

Advanced integration options include:

Our complete solutions support Class VI medical-grade pad printing, high-speed part decoration, and inline quality control. Deco Tech’s automation packages reduce operator handling, minimize downtime, and deliver consistent, repeatable print results across production shifts.

Printcolor of Switzerland is an ISO 9001-certified manufacturer of high-performance pad printing inks trusted worldwide for precision decoration. Their 700 Series pad printing ink systems offer exceptional opacity, adhesion, and print definition on plastics, metals, glass, and coated surfaces. Available in glossy or matte finishes, these inks deliver consistent results in demanding production environments.

Printcolor inks are widely used in automotive, electronics, and consumer goods applications, and are certified for both interior and exterior use. The line also includes USP Class VI medical-grade pad transfer inks, approved for printing on implantable medical devices and other sensitive substrates.

Deco Tech is the exclusive North American distributor of Printcolor Screen Ltd., providing full technical support, color matching, compliance documentation, and fast delivery across the U.S. and Canada.

Deco Tech offers industrial-grade pad printing drying conveyors engineered for seamless integration into your production line. Our IR (infrared) hot air dryers and UV curing conveyor systems are ideal for drying pad printing inks on plastics, metals, glass, wood, and coated substrates. These systems help reduce downtime, increase throughput, and ensure consistent curing results across multi-shift operations.

We offer both standalone drying conveyors and inline curing systems, available in compact tabletop formats or large-scale conveyorized models. Whether you require UV curing for high-opacity inks or efficient IR drying for heat-sensitive materials, our equipment is built for reliability and ease of use.

All of our pad printing conveyor dryers are built with adjustable belt speed, variable temperature control, and optional shielding to meet safety and cleanroom requirements. Deco Tech’s expert team will help you size, configure, and support the right solution based on your material, substrate, ink type, and curing requirements.

Deco Tech manufactures precision-engineered silicone pad printing pads at our facility in Southern California, supporting customers across North America with fast delivery and consistent quality. Our pads are used in demanding applications including medical device printing, electronics, automotive components, promotional items, and specialty plastics.

We offer a wide range of shapes, sizes, and Shore A durometers to match virtually any artwork or part geometry — from small, intricate logos to large, curved or recessed surfaces. Each pad is molded from our proprietary, high-performance silicone compound that ensures excellent ink pickup and release, minimal image distortion, and extended pad life.

Our silicone printing pads are compatible with all major pad printing machines and ink types, including 1-component, 2-component, and UV-curing inks. Whether you're printing on plastic housings, glass panels, anodized aluminum, or coated substrates, Deco Tech provides the right pad solution for clean, repeatable results.

Need help selecting the right pad? Our in-house experts are ready to assist with application matching, custom pad development, and technical support.

Deco Tech supplies medical-grade pad printing inks from Printcolor of Switzerland, certified to USP Class VI standards for use on medical devices that come into direct or indirect contact with the human body. These biocompatible pad printing inks are rigorously tested for systemic toxicity and intracutaneous reactivity, meeting the FDA’s safety requirements.

Printcolor has received Class VI certification for the following ink series:

These certifications were achieved using black and white ink formulations, though additional colors in the same series have also passed cytotoxicity testing.

Deco Tech provides full support for medical manufacturing applications, including cytotoxicity reports, technical documentation, and application guidance for Class VI-compliant production. Whether you’re decorating syringes, catheters, housings, or surgical tools, our certified ink systems help ensure compliance, durability, and print clarity on even the most delicate medical substrates.

Deco Tech designs and manufactures custom pad printing fixtures—also known as nesting fixtures—to hold your parts securely during the printing process. Our in-house machine shop produces both one-off and multi-cavity fixtures for manual, semi-automatic, and fully automated pad printing systems.

Whether you need a precision-machined part-holding fixture for a curved medical component, an irregular promotional item, or a molded plastic part, we can build tooling that ensures perfect repeatability, print alignment, and operator efficiency.

We offer:

From concept to installation, our fixturing team works with your engineering and production departments to deliver tailored solutions that enhance print quality and reduce setup time.

Deco Tech offers a complete selection of pad printing plates—also called clichés—including water wash, alcohol wash, and laser-etchable polymer clichés. We also supply steel clichés in both thin (0.5mm) and thick (10mm) formats, available pre-cut to size or fully customized. Our cliché materials are compatible with leading pad printing machines including microPrint, Kent, Teca-Print, and more. Need help etching your design? We provide full artwork processing and cliché etching services in-house. Most orders ship within 24–48 hours.

At Deco Tech, we supply a full range of hardened steel and ceramic pad printing ink cup rings designed to fit nearly all major pad printing machine brands, including microPrint, Tosh, Kent, Comec, and others. Our ink cup rings are available in standard sizes from 40mm to 180mm and are built for durability, solvent resistance, and long service life.

Each ring is precision-machined to deliver a clean doctoring edge and tight seal, ensuring consistent ink transfer and minimizing print defects. We also offer complete ink cup assemblies, including housings, seals, and replacement rings for both OEM and retrofit applications.

For companies looking to modernize older machines, Deco Tech provides retro-fit kits that convert open inkwell systems to sealed ink cup technology. These upgrades simplify cleanup, reduce solvent evaporation, and improve overall print quality.

We also offer microPrint’s advanced magnetic ink cup system, which eliminates mechanical fasteners and provides even, automatic pressure across the ceramic or steel ring. This innovation is ideal for demanding print jobs in medical, industrial, and electronics sectors where precision is critical.

Need help selecting the right ink cup or retrofit solution? Contact our expert team for guidance on sizing, machine compatibility, and application-specific recommendations.

Deco Tech offers a complete line of high-performance cleaning chemicals and supplies for pad printing and screen printing production environments. Our cleaning solutions are engineered to effectively remove solvent- and UV-based pad printing inks from ink cups, clichés, silicone pads, and doctoring rings—without damaging sensitive components.

We proudly offer our low-VOC Neo-Solv 114 universal ink cleaner, developed to meet strict California SCAQMD environmental compliance standards. This versatile solvent provides powerful cleaning action while reducing operator exposure to hazardous fumes. It’s ideal for use in manual wash stations, ultrasonic cleaners, and automatic parts washers.

Whether you're using alcohol-based or two-component inks, our line of pad printing cleaning products ensures consistent performance and reduced downtime. We also provide support for matching our cleaners with your existing equipment or washout systems to maximize effectiveness and compatibility.

Looking for eco-friendly options? Ask us about water-based cleaning alternatives for specific ink types and substrates. All our cleaning products are in stock and ship quickly from our Southern California facility.